team boiler price and boiler welding

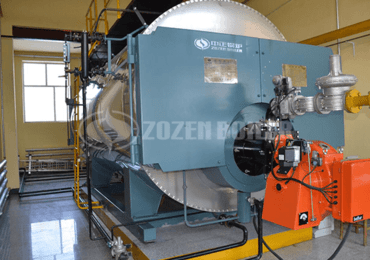

Advanced submerged arc automatic welding technology is adopted for main welding seams to ensure welding quality. All major welds are 100% radiographically inspected according to the requirements of the steam boiler safety technical supervision according to the II pole certification standard. The main body of the steam boiler adopts a horizontal internal combustion full wet back three-cycle structure.

The price of the steam boiler and the back of the boiler smoke box seal are made of high temperature resistant asbestos graphite material, and the seal is reliable, ensuring that the steam boiler will not leak when it is operated under the condition of slight positive pressure.

Threaded tube: On the two-channel convection heating surface of a steam boiler, we use a threaded tube to promote efficient heat transfer. The enhanced heat transfer function makes the steam boiler more efficient, and one threaded tube is equivalent to 2.4 tubes. When the fluid flows in the duct, the fluid velocity near the tube wall is very low, so the body is called the boundary layer at the tube wall. In a series of thermal resistances in which the flue gas transfers heat to the water outside the pipe, the thermal resistance of the boundary layer is large, but the boundary layer is thin. As long as the boundary layer is slightly disturbed, such as extruding a boss on the inner wall of an ordinary pipe, interference with the boundary layer will greatly reduce the thermal resistance. Threaded pipe is an effective method.

Leave a Reply