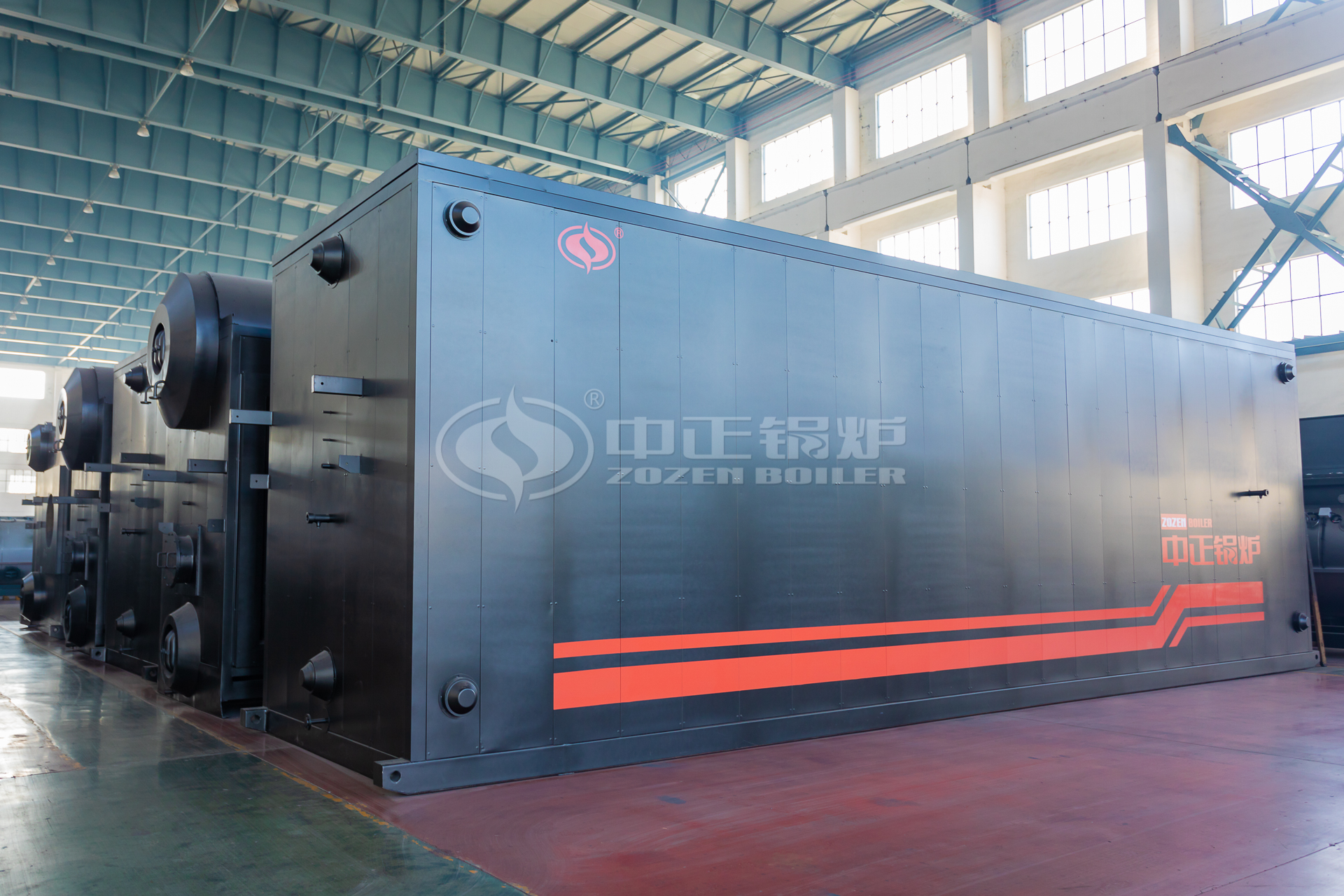

DZL Series Coal Fired Hot Water Boiler

Product Thermal Capacity:1.4-7 MW

Working Pressure: 0.7-1.25 MPA

Available Fuel: Bituminous Coal,Lean Coal,Anthracite

Available Industries: Heating, Hotels, Schools, Hospitals

DZL Series Coal Fired Boiler Advantages

CNC manufacturing technology

- The key processing technologies such as steel plate blanking, circling, drum and tube plate drilling adopt advanced CNC machining to reduce the assembly stress and prolong the service life of the boiler.

- Steel tube cutting, thread tube pressing and convection tube processing all adopt advanced CNC technology.

- Arched tube sheets and threaded fire tube was first adopted in China to increase heat transfer and completely solve the problem of cracking of the back tube sheet.

- Chain grate plate and back smoke chamber plate is cut by CNC plasma cutting machine, which looks neat and beautiful.

Advanced welding process

- The vertical and circumferential seam welding of the boiler adopts advanced automatic submerged arc welding technology to ensure the welding quality. All vertical and circumferential welds will go through 100% ray detection.

- The welding of smoke tube and the tube plate adopts pre-expansion to eliminate the gap between the tube and tube plate, then be welded by automatic argon arc welding, which effectively eliminate stress and prolong boiler life.

- The flange of the socket is welded by robots.

- The chain grate is manufactured by our factory, and it is tested for 72 hours before leaving the factory to ensure that the tightness is moderate and won’t deviate.

Precision parts processing

- Advanced manufacturing technology, using assembly line automatic spinning manufacturing.

- Enhance heat transfer and raise boiler thermal efficiency.

- Threaded smoke tubes are highly efficient heat transfer elements which is from many years research of our company. After continuous optimization, the heat transfer coefficient is 1.8 times higher than normal smoke tubes.

Unique structural design

- Disturbed flue gas to ensure complete combustion of volatile matters.

- The air volume takes about 30% of the total amount, and the wind speed is 50m³.

- The independent secondary fan makes it easy to control and adjust the wind volume and pressure.

- The high-temperature smoke generated by the combustion first enters the horoscope flue on both sides of the body from the tail (in this case, the boiler is water tube type), and the flue gas flows outside the tube.

- The flue gas cooled by the horoscope flue enters the threaded tube (in this case the boiler is fire tube type) arranged in the drum from the front smoke chamber.

- The flue gas will be exhausted from the back smoke chamber, this design fundamentally solves the problem of cracking of the tube sheet of a simple fire tube boiler.

Auxiliaries

- Feeder: Feeding fuel equally to avoid flashback.

- Gearbox: Designing reasonable rotating speed according to the combustion speed to make sure the fuel burning completely.

- Cover plates: Cold-rolled pressed plates, strong and elegant.

- Inspection door: reasonable manhole and hand hole layout, easy for maintenance. Inspection doors in furnaces for easy access and maintenance.

DZL Series Coal Fired Boiler Specification

| Model | Rated thermal power (MW) | Rated working pressure (MPa) | Rated output water temperature (℃) | Thermal efficiency (%) | Maximum transport dimension (m) |

| DZL1.4-0.7/95/70-AⅡ | 1.4 | 0.7 | 95 | >80 | 5.30×2.40×3.40 |

| DZL2.8-0.7/95/70-AⅡ | 2.8 | 0.7 | 95 | >80 | 6.00×2.70×3.60 |

Leave a Reply