Understanding Coal Boiler Efficiency in Industrial Steam Applications

Coal boiler efficiency is a critical performance indicator for industries that rely on coal-fired steam systems as a stable and economical heat source. In industrial production, steam boilers are often required to operate continuously under varying load conditions, and coal boiler efficiency directly affects fuel consumption, operating costs, and environmental performance. A higher level of coal boiler efficiency means that more heat released from coal combustion is effectively converted into usable steam, while less energy is lost through exhaust gas, incomplete combustion, or heat dissipation.

ZOZEN BOILER, as an experienced industrial boiler manufacturer, has continuously optimized coal-fired boiler technology to help customers improve coal boiler efficiency while maintaining stable steam output and reliable operation. By integrating advanced design concepts with extensive project experience across different industries and regions, ZOZEN BOILER provides coal-fired steam boiler solutions that balance efficiency improvement, operational stability, and practical applicability under real working conditions.

Enhancing Coal Boiler Efficiency with ZOZEN SZL and DZL Coal-Fired Steam Boilers

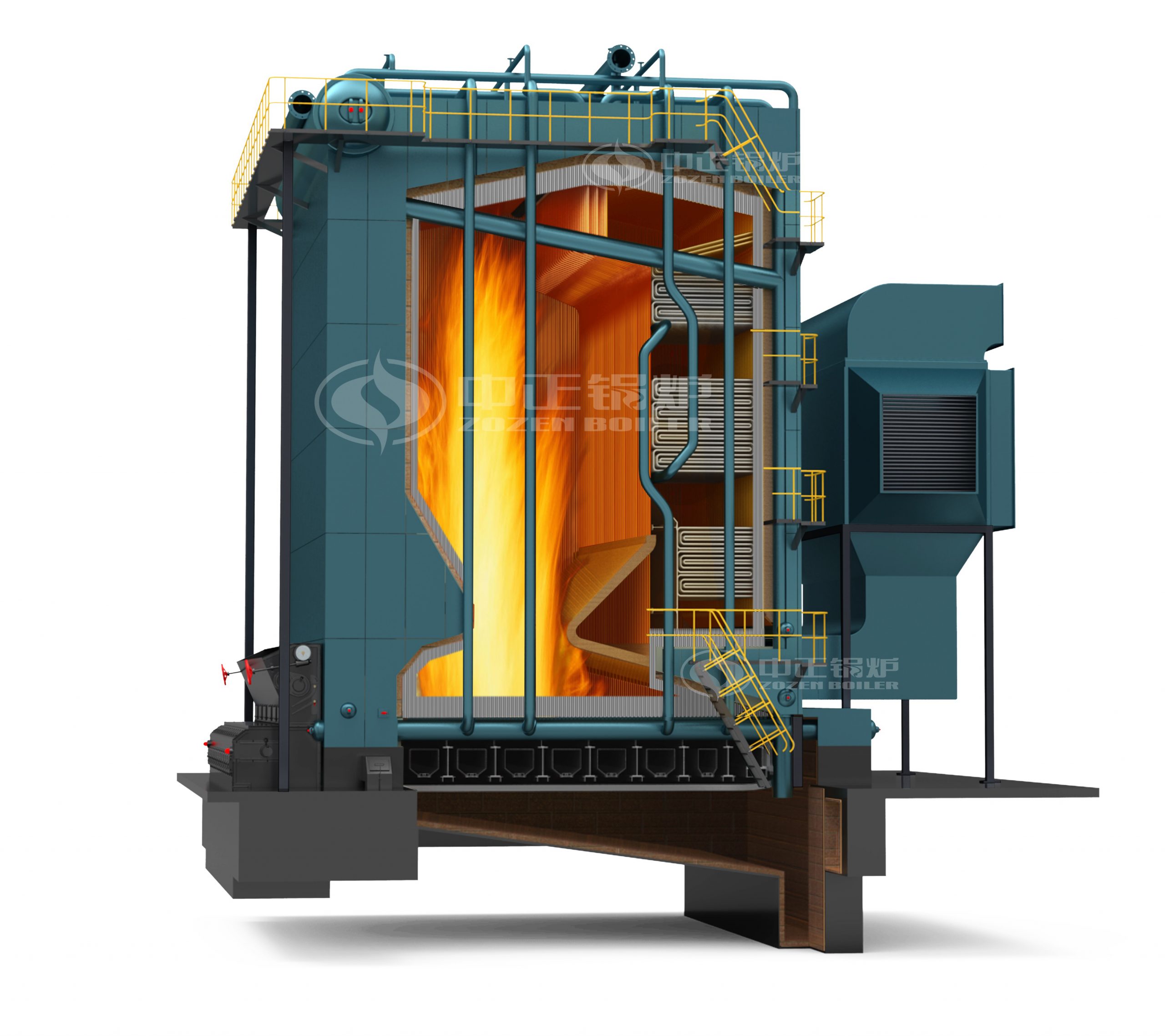

ZOZEN BOILER offers multiple coal-fired steam boiler solutions designed to improve coal boiler efficiency through optimized structure, combustion design, and heat transfer systems. Among them, the SZL coal-fired steam boiler and the DZL coal-fired steam boiler are two representative products that have been widely applied in industrial production.

ZOZEN 10 ton SZL coal-fired steam boiler

The SZL series coal-fired steam boiler is a longitudinally arranged double-drum water tube boiler equipped with a chain grate combustion system. This structure is specifically designed to support stable combustion and efficient heat transfer, which are essential factors influencing coal boiler efficiency in medium and large industrial applications.In the SZL boiler, the furnace is formed by densely arranged water-cooled wall tubes combined with front and rear arches. This design significantly increases the radiant heating surface area, allowing more heat released from coal combustion to be absorbed by the water walls. As a result, radiant heat utilization is enhanced, contributing directly to improved coal boiler efficiency.

Behind the furnace, the boiler body is equipped with multiple passes of convective tube bundles. These convective heating surfaces further recover heat from high-temperature flue gas before it exits the boiler, reducing exhaust heat loss and improving overall thermal utilization. The combination of radiant and convective heating surfaces enables the SZL boiler to maintain stable steam generation while effectively controlling energy loss.

Air distribution plays a crucial role in coal boiler efficiency, particularly when dealing with varying coal qualities. The SZL coal-fired steam boiler is designed with multiple independent air chambers at the base of the boiler. Each air chamber is equipped with adjustable air doors, allowing operators to regulate airflow precisely according to combustion stages and coal characteristics. This precise air supply helps ensure sufficient oxygen for combustion while avoiding excessive excess air, which can otherwise reduce coal boiler efficiency.

The DZL series coal-fired steam boiler is another important product developed by ZOZEN BOILER to enhance coal boiler efficiency in small to medium capacity applications. The DZL boiler adopts a single-drum structure with a chain grate combustion system and a compact horizontal arrangement, making it suitable for industrial users with limited space while maintaining stable steam output.

Like the SZL series, the DZL boiler also emphasizes stable combustion through controlled air distribution and reliable grate operation. This ensures complete coal combustion, reduces unburned carbon in ash, and contributes to consistent coal boiler efficiency during long-term operation.

Improving Coal Boiler Efficiency for an AAC Block Manufacturer in Indonesia

REXCON INDONESIA is a professional autoclaved aerated concrete block manufacturer located in Indonesia. As the company expanded its production capacity, the demand for stable and efficient steam supply increased accordingly. Steam is a critical energy source in AAC block production, supporting processes such as curing and material conditioning, which directly affect product quality and production continuity.

To meet its expanded production needs, PT. REXCON INDONESIA decided to invest in a new coal-fired steam boiler system with a rated capacity of 10 tons per hour. Given the importance of coal boiler efficiency to long-term operating costs and production stability, the company placed significant emphasis on selecting a boiler supplier with proven technical strength and reliable project experience.

During the initial communication stage, ZOZEN BOILER’s sales manager conducted a detailed assessment of the customer’s production process and operating requirements. By understanding the specific steam demand characteristics of AAC block manufacturing, ZOZEN BOILER was able to propose a coal-fired steam boiler solution aligned with the customer’s efficiency and reliability expectations.

In addition to technical discussions, the sales manager presented ZOZEN BOILER’s successful service cases in the Indonesian market. These real project examples demonstrated how ZOZEN coal-fired boilers perform under local operating conditions, helping the customer gain confidence in the company’s ability to deliver stable performance and satisfactory coal boiler efficiency.

Throughout the communication process, ZOZEN BOILER also shared detailed information about its manufacturing capabilities, including production facilities, processing equipment, and quality control practices. This transparency allowed the customer to better understand how design, manufacturing precision, and quality management contribute to coal boiler efficiency and long-term operational stability.

After comprehensive evaluation, PT. REXCON INDONESIA decided to increase its investment budget and select ZOZEN BOILER’s 10-ton coal-fired steam boiler. This decision reflected the customer’s recognition of ZOZEN BOILER’s enterprise scale, manufacturing process, and product quality, as well as confidence in the expected coal boiler efficiency of the selected system.

Why ZOZEN BOILER Stands Out in Coal Boiler Efficiency Optimization

Coal boiler efficiency is not determined by a single parameter but by the combined performance of combustion organization, heating surface design, air distribution accuracy, and manufacturing quality. ZOZEN BOILER’s coal-fired steam boiler solutions emphasize balanced design and practical performance rather than extreme configurations, ensuring that coal boiler efficiency can be maintained under real industrial operating conditions.

Beyond equipment design, ZOZEN BOILER supports coal boiler efficiency through its comprehensive service approach. From pre-sales technical consultation and system selection to manufacturing, delivery, and after-sales support, ZOZEN BOILER helps customers achieve stable operation and consistent efficiency over the boiler’s service life.

For industrial enterprises seeking reliable improvements in coal boiler efficiency, ZOZEN BOILER offers coal-fired steam boiler solutions grounded in engineering experience, manufacturing quality, and practical application results. By choosing ZOZEN BOILER, customers gain not only a coal-fired boiler but also a long-term partner committed to stable operation, efficiency optimization, and sustainable industrial development.

Leave a Reply