Biomass Boiler Malaysia: Industrial Energy Solutions for Sustainable Production

A typical biomass boiler Malaysia project must address several key operational considerations, including fuel availability, combustion stability, thermal efficiency, and long-term maintenance. Local biomass resources such as wood chips, rice husk, palm kernel shells, and other agricultural residues are widely available, but their varying moisture content and particle size place higher demands on boiler design. For industrial users, selecting a biomass boiler supplier with proven engineering capability and international project experience is essential to ensure smooth operation under real-world conditions.

Against this backdrop, ZOZEN BOILER has become a trusted name for enterprises evaluating biomass boiler Malaysia options. With decades of experience in industrial boiler manufacturing and a strong export presence in Southeast Asia, ZOZEN provides customized biomass boiler systems that align with Malaysian operating environments, fuel characteristics, and regulatory expectations. By combining mature combustion technology with robust structural design, ZOZEN helps users achieve a balance between energy efficiency, operational reliability, and environmental responsibility.

SZL Biomass Steam Boiler from ZOZEN: Design Features and Technical Advantages

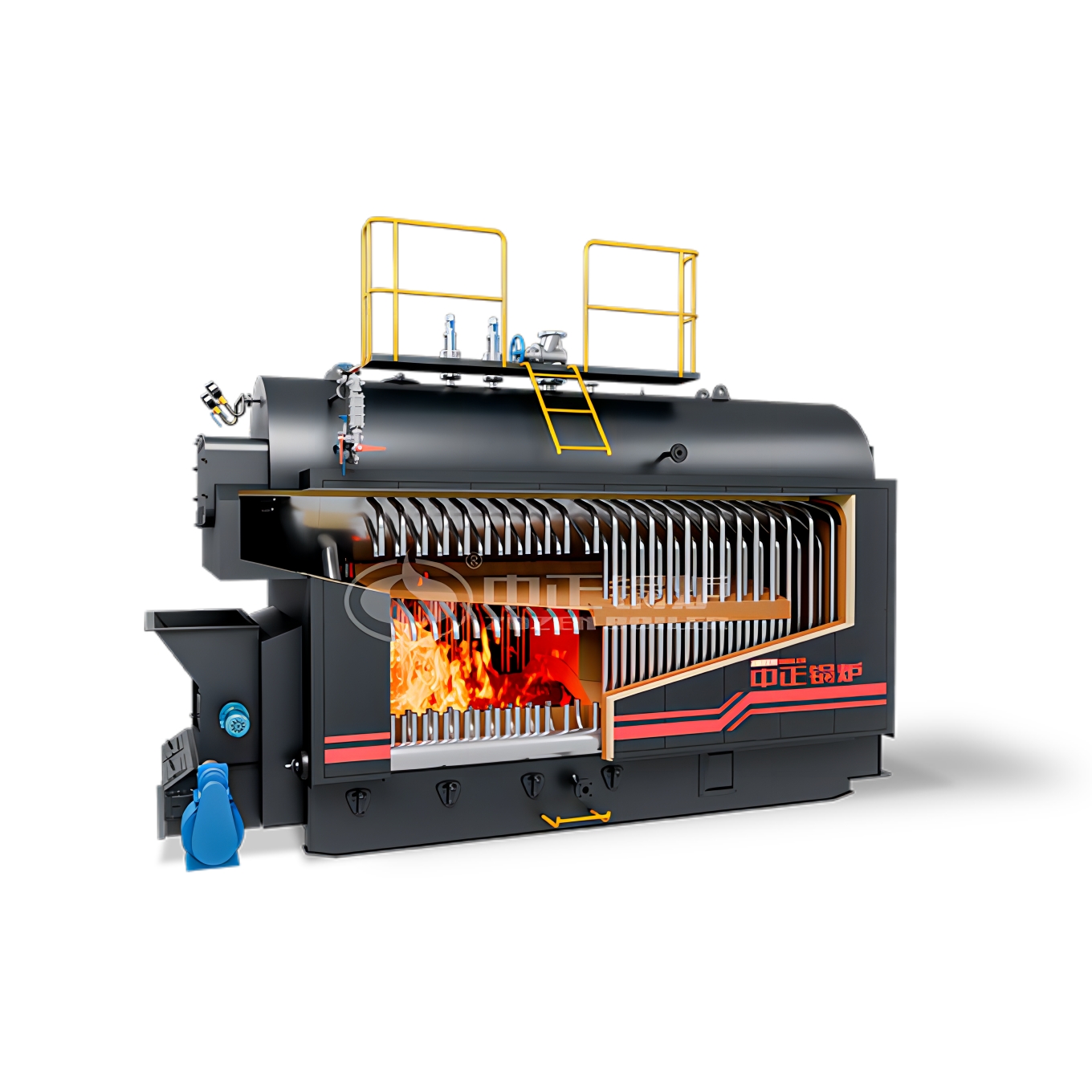

Among ZOZEN’s biomass product portfolio, the SZL biomass steam boiler has gained wide recognition in biomass boiler Malaysia projects that require medium to large steam capacity and continuous operation. The SZL series is a chain grate water tube boiler featuring a horizontal double-drum structure and longitudinal arrangement, a configuration that supports stable combustion and effective heat transfer under variable load conditions.

ZOZEN 4 ton SZL biomass-fired steam boiler

The SZL biomass steam boiler is designed to handle a broad range of biomass fuels commonly available in Malaysia. Its chain grate combustion system works in combination with an independent air chamber design, allowing precise air distribution across different combustion zones. This arrangement improves fuel adaptability and ensures that biomass fuels with varying ash content and calorific value can burn more completely, reducing unburned carbon loss and improving overall combustion stability. For biomass boiler Malaysia users, this flexibility is particularly valuable in managing fuel supply fluctuations.

From a heat transfer perspective, the boiler furnace adopts a densely arranged membrane water wall tube structure. This design significantly increases the radiant heating surface area, enabling more efficient absorption of high-temperature heat released during biomass combustion. The convection section, arranged behind the furnace, further recovers heat from flue gas before it exits the system. Under rated operating conditions, the SZL biomass boiler achieves thermal efficiency exceeding 86 percent, supporting lower fuel consumption per unit of steam produced.

Operational reliability is another important factor in biomass boiler Malaysia installations. The SZL series emphasizes mechanical strength and long service life, with key pressure components manufactured from qualified boiler steel and welded using standardized procedures. The chain grate is engineered for continuous operation and reduced wear, while the ash discharge system is designed to handle biomass ash characteristics effectively. These features contribute to stable long-term operation and help industrial users reduce unplanned downtime.

In terms of environmental performance, the SZL biomass steam boiler supports the integration of flue gas treatment equipment such as dust collectors and desulfurization units according to project requirements. By combining clean biomass fuel with appropriate emission control measures, the system supports compliance with environmental standards while aligning with corporate sustainability goals. For enterprises evaluating biomass boiler Malaysia solutions, this balanced approach to efficiency and emissions is a key consideration.

Case Study: Biomass Boiler Application in Health Food Manufacturing

The customer in this project sought a biomass boiler Malaysia solution that could support continuous production while reducing operating costs and environmental impact. Traditional fossil-fuel-based steam systems were increasingly challenged by fuel price volatility and emission concerns, prompting the customer to explore biomass energy as a long-term alternative. Stability, efficiency, and adaptability were identified as critical requirements for the new boiler system.

After a detailed evaluation, ZOZEN BOILER recommended the SZL series biomass steam boiler as a tailored solution. The chain grate combined with an independent air chamber system enabled precise control of the fuel-to-air ratio, ensuring stable combustion even when biomass fuel properties varied. This feature was particularly important for maintaining steady steam output during extraction and sterilization stages, where fluctuations could negatively affect product consistency.

The boiler body adopted a dense membrane water wall tube arrangement, which significantly increased radiant heat absorption and contributed to high thermal efficiency. With optimized heat transfer and well-matched auxiliary systems, the SZL biomass boiler delivered reliable steam supply while effectively reducing fuel consumption. The system’s operational performance met the customer’s expectations for energy savings without compromising process stability.

From an environmental perspective, the biomass boiler system utilized clean, renewable biomass fuel and was equipped with appropriate flue gas treatment components. This configuration effectively reduced particulate matter, sulfur dioxide, and nitrogen oxide emissions, supporting the customer’s commitment to green production and sustainable development. The project demonstrated how a well-designed biomass boiler Malaysia solution could align industrial performance with environmental responsibility.

Why ZOZEN BOILER Is a Reliable Choice for Biomass Boiler Malaysia Projects

When evaluating biomass boiler Malaysia suppliers, industrial users often prioritize technical maturity, project experience, and service capability. ZOZEN BOILER offers a comprehensive approach that goes beyond equipment supply, providing engineering support throughout the project lifecycle. From fuel analysis and system design to installation guidance and commissioning assistance, ZOZEN helps customers build biomass boiler systems that perform reliably under real operating conditions.

The SZL biomass steam boiler reflects ZOZEN’s emphasis on practical engineering rather than theoretical optimization. By focusing on combustion stability, structural durability, and ease of operation, ZOZEN delivers biomass boiler Malaysia solutions that support long-term industrial use. This approach helps customers manage operational risks while achieving predictable energy performance.

Another advantage lies in ZOZEN’s experience in overseas markets, particularly in Southeast Asia. Familiarity with regional fuel characteristics, climatic conditions, and industrial applications allows ZOZEN to adapt biomass boiler designs to local requirements. This regional experience reduces project uncertainty and supports smoother system integration for Malaysian users.

In conclusion, biomass boiler Malaysia projects require more than basic equipment selection. They demand a partner with proven technology, realistic engineering design, and a clear understanding of industrial operating needs. ZOZEN BOILER, with its SZL biomass steam boiler and extensive international project experience, provides a dependable option for enterprises seeking efficient, stable, and environmentally responsible biomass energy solutions. For companies planning to invest in biomass boiler Malaysia systems, ZOZEN offers the technical foundation and service support needed for long-term success.

Leave a Reply