Boiler 6 ton:Reliable 6 Ton Industrial Steam Boiler Solutions from ZOZEN Boiler

In modern industrial production, the boiler 6 ton capacity range has become one of the most widely used solutions for medium-sized enterprises. A boiler 6 ton can provide stable and efficient steam output for manufacturing processes such as feed production, textile dyeing, food processing, chemical synthesis, and building materials drying. With a rated evaporation capacity of 6 tons per hour, this type of boiler offers an ideal balance between output and efficiency, ensuring that industrial users achieve reliable energy supply without excessive fuel consumption.

As global industries transition toward cleaner and more efficient energy systems, the selection of a high-performance boiler 6 ton has become a crucial factor for maintaining competitiveness. ZOZEN Boiler, a well-established Chinese manufacturer with over 35 years of experience in the field, has become a trusted partner for industrial customers worldwide. With its advanced production facilities, professional engineering team, and a wide range of energy-saving boiler products, ZOZEN provides customized solutions that meet the diverse requirements of modern industrial applications.

ZOZEN SZL Coal-Fired Steam Boiler and WNS Gas/Oil-Fired Steam Boiler

Among ZOZEN’s comprehensive industrial product portfolio, the SZL series coal-fired steam boiler and the WNS series gas/oil-fired steam boiler are two representative models that have been successfully applied across numerous industries. Each boiler 6 ton in these series features optimized design, high efficiency, and excellent durability, reflecting ZOZEN’s consistent focus on quality and reliability.

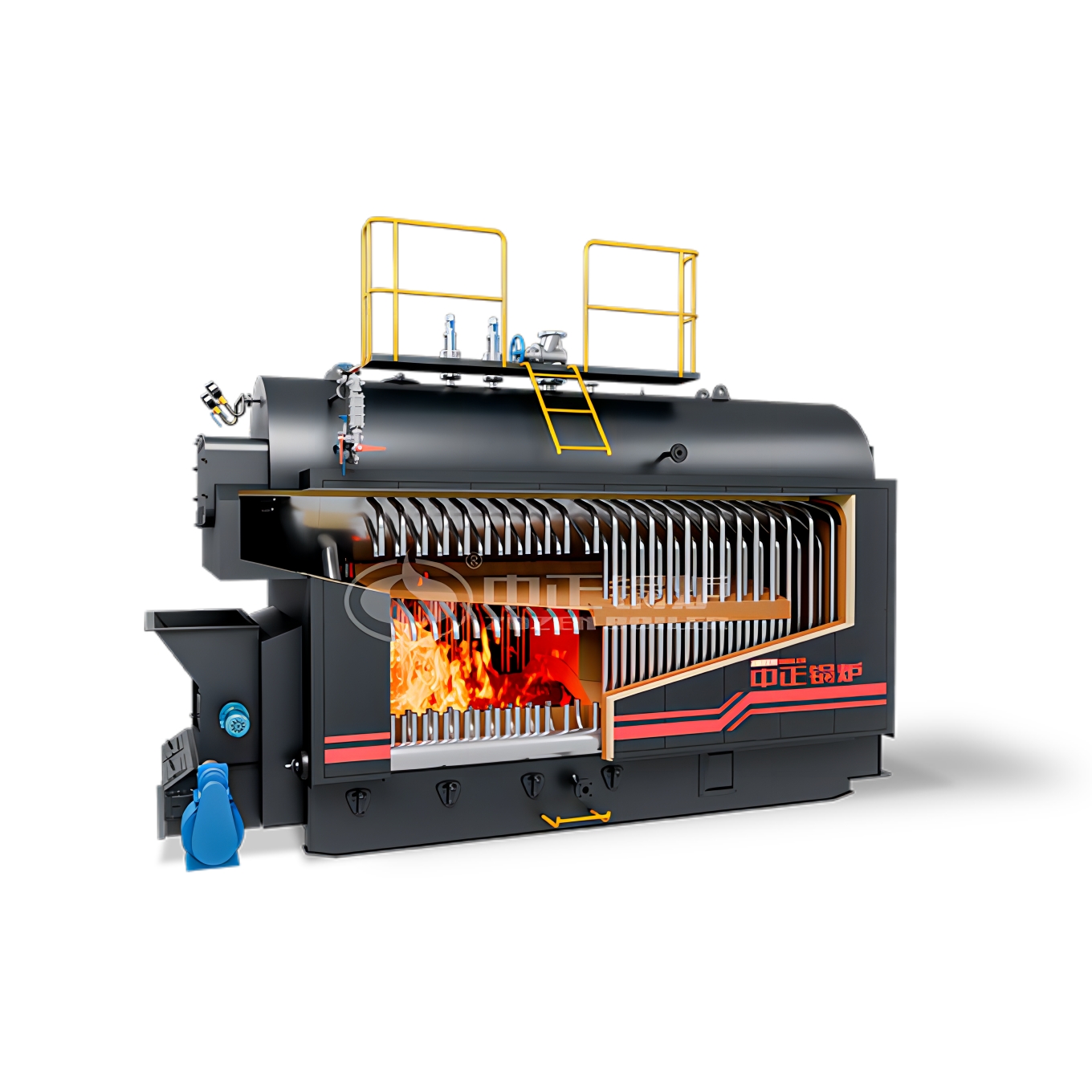

The SZL series coal-fired steam boiler is designed with a horizontal double-drum chain grate structure. The upper part of the boiler consists of the heat receiving surfaces, while the lower part is equipped with the combustion chamber and mechanical grate system. The boiler 6 ton SZL model has a rated evaporation capacity of 6 tons per hour, with a steam temperature of approximately 194°C and a feed water temperature of 20°C. The front and rear walls of the furnace are constructed with membrane-type water-cooled walls, forming a closed combustion chamber that efficiently absorbs radiant heat from the flame.

ZOZEN 6 ton SZL coal-fired boiler

The convective heating surfaces are arranged with densely packed tube bundles between the upper and lower drums, where the high-temperature flue gas passes through and transfers additional heat before being directed into a separately installed economizer. The flue gas then moves to the dust removal unit and is finally released through the chimney. This well-designed heat exchange system ensures efficient energy recovery and helps enterprises reduce exhaust emissions in line with local environmental standards.

In addition to structural optimization, the SZL boiler 6 ton adopts advanced combustion air distribution and grate drive systems, which enable stable fuel feeding, complete combustion, and low unburned carbon content in the ash. The water circulation within the boiler is carefully designed to ensure uniform heating and prevent local overheating. Furthermore, ZOZEN’s manufacturing precision ensures long-term operational stability and reduced maintenance costs. This model is especially suitable for industries with a steady demand for saturated steam, such as feed processing, food manufacturing, and material drying.

The fully automatic control system enables intelligent adjustment of fuel and air supply, maintaining stable pressure and temperature during operation. The integrated safety interlock, alarm, and protection systems guarantee safe and reliable functioning throughout its service life.

ZOZEN 6-Ton SZL Boiler in the Feed Processing Industry

In the feed manufacturing industry, processes such as conditioning, pelleting, drying, and sterilization all rely on steam as the primary energy source. Stable steam supply not only affects product quality but also determines production efficiency and energy consumption levels. A leading feed company specializing in the production and research of feed and concentrated feed recently partnered with ZOZEN Boiler to enhance its production reliability and reduce operational costs.

Based on the company’s feed processing requirements and production scale, ZOZEN provided a customized boiler 6 ton SZL coal-fired steam boiler (model SZL6-1.25-AⅡ). The boiler has a rated evaporation capacity of 6 tons per hour, with a steam temperature of 194°C and a feed water temperature of 20°C, precisely meeting the customer’s process heating needs.

The boiler adopts a compact and practical assembly structure consisting of two major components — the upper section comprising the heat exchange surfaces and the lower section containing the combustion system. The furnace front wall and surrounding surfaces are fitted with water-cooled walls that absorb radiant heat and ensure efficient thermal transfer. Between the upper and lower drums, a set of densely arranged convection tubes allows flue gas to flow through and release additional heat before entering the economizer.

The separated economizer efficiently utilizes the residual heat of the flue gas, improving the overall thermal efficiency of the boiler 6 ton. After passing through the economizer and the dust removal system, the clean flue gas is discharged through the chimney, effectively meeting the region’s environmental emission standards. The advanced design also minimizes soot accumulation, ensuring cleaner combustion and easier maintenance.

Since its commissioning, the ZOZEN boiler 6 ton has provided a stable and reliable steam supply for the company’s daily feed production. It ensures the smooth operation of conditioning and pelleting processes, where consistent steam temperature and pressure are critical for product uniformity. The feed manufacturer reported notable reductions in fuel consumption and visible improvement in overall plant efficiency. By integrating ZOZEN’s advanced boiler technology, the company successfully achieved its goals of lowering operational costs and adhering to environmental regulations.

Partnering with ZOZEN for Efficient 6-Ton Boiler Solutions

Selecting a suitable boiler 6 ton is vital for industries seeking reliable steam supply and sustainable operation. ZOZEN Boiler provides high-quality products, advanced technologies, and complete service systems to meet the diverse energy needs of global users. With its proven SZL coal-fired and WNS gas/oil-fired steam boilers, ZOZEN helps enterprises achieve energy efficiency, environmental compliance, and stable production performance.

Through continuous innovation, strict quality management, and global service coverage, ZOZEN Boiler remains a dependable partner for industrial customers seeking efficient and environmentally friendly boiler 6 ton solutions.

Leave a Reply