Textile Boiler: Engineering Precision for Sustainable Fabric Production

The textile industry’s intricate production processes—from dyeing and finishing to fabric drying and steam curing—demand thermal systems that deliver unwavering steam quality, responsive load management, and operational resilience. As global sustainability pressures intensify, textile manufacturers increasingly seek textile boiler solutions that balance energy-intensive operations with environmental responsibility. Traditional coal-fired systems face mounting regulatory hurdles, while inconsistent steam quality disrupts delicate coloration processes and fabric integrity. This convergence of technical and ecological challenges has propelled biomass-fueled textile boiler technology to the forefront, offering a pathway to decarbonization without compromising production stability. ZOZEN BOILER, with decades of specialization in industrial thermal systems, addresses these sector-specific demands through engineering that prioritizes fuel flexibility, steam purity, and spatial efficiency—proven across textile hubs from Southeast Asia to South America.

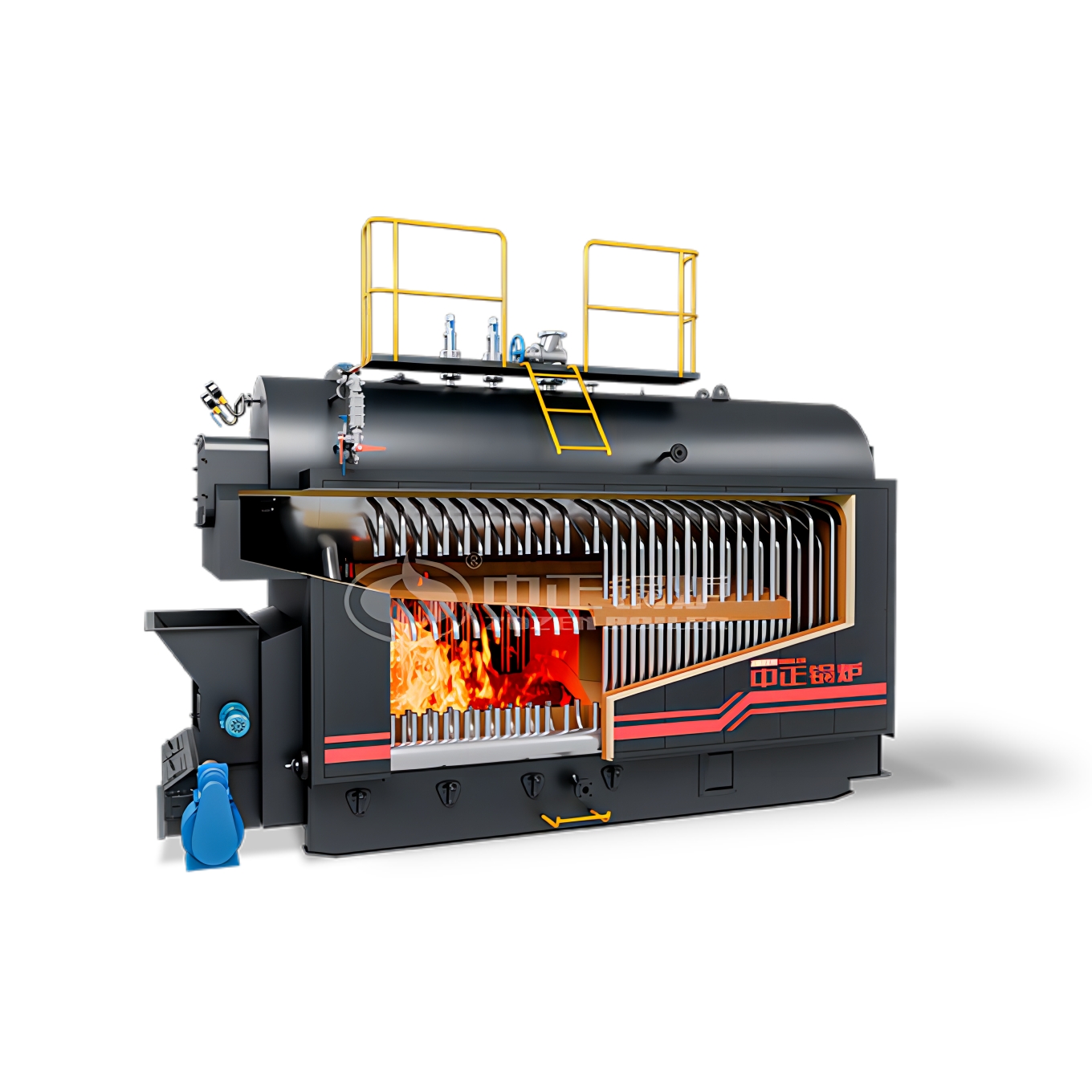

ZOZEN’s DZW Reciprocating Grate Biomass Boiler: Tailored for Textile Excellence

The core of ZOZEN Textile boiler product portfolio is the DZW series reciprocating grate biomass steam boiler, designed specifically for the volatile textile production environment. Unlike traditional biomass boilers prone to ash accumulation and unstable combustion, this system directly addresses the textile industry’s pain points through key innovations.

The DZW series third-generation biomass boiler is a three-drum water-tube boiler independently developed by ZOZEN Boiler. The boiler features an assembled structure consisting of two large sections: the upper section serves as the heating surface of the boiler, and the lower section houses the combustion equipment. Water-cooled walls surround the front of the boiler, connecting the upper section to the drum and the lower section to the header, forming the combustion chamber to absorb radiant heat from the furnace. At the rear, a convection tube bundle is arranged between the upper and lower drums. After the fuel is burned in the furnace, the high-temperature flue gas exits the furnace and horizontally flushes the heating surfaces of the convection tube bundle, then enters the economizer and finally the dust collector, where it is discharged through the chimney.

The reciprocating grate mechanism represents a paradigm shift in biomass combustion dynamics. Traditional fixed grates often cause fuel bridging and uneven combustion, especially when processing agricultural residues such as cotton stalks or rice husks, common in textile regions. The DZW series’ reciprocating grates continuously agitate the fuel bed, preventing clumping and ensuring uniform propulsion during the drying, combustion, and burnout phases. This dynamic action is crucial for high-moisture biomass streams, eliminating the need for energy-intensive pre-drying while maintaining constant steam pressure—essential for dyeing consistency and fabric shrinkage control.

ZOZEN 15 ton DZW biomass boiler

Furthermore, water-cooled furnace walls mitigate thermal stresses caused by frequent load fluctuations during intermittent dyeing, while reinforced convection tube bundles resist attack from alkaline biomass ash. Sootblowing devices are located on the rear convection heating surface, with holes for sootblowing pipes located at the top of the furnace. Sootblowing types are selected based on the fuel type, allowing for ash cleaning without shutting down the boiler, enabling uninterrupted steam generation—critical for round-the-clock textile boiler. The advanced convection heating surface layout reduces the burden on the dust collector, providing a more environmentally friendly solution under the same conditions.

Powering Sustainable Textile Innovation in Pakistan

Soorty Enterprises, a Pakistan-based textile conglomerate founded in 1983, exemplifies the industry’s shift toward integrated sustainability. As a global leader in denim manufacturing serving major European and American brands, the company faced dual imperatives: reducing reliance on fossil fuels while ensuring uninterrupted steam supply for its complex finishing processes. Their existing coal-fired systems struggled with inconsistent steam quality and rising regulatory pressures, necessitating a solution that could leverage locally available biomass without compromising production continuity.

After rigorous evaluation, Soorty selected ZOZEN’s 15-ton reciprocating grate three-drum biomass steam boiler—a decision driven by three critical factors. First, the boiler’s three-drum design enabled ash management without operational shutdowns, directly addressing textile boiler’s intolerance for steam interruptions. Unlike conventional double-drum boilers requiring frequent manual cleaning, ZOZEN’s configuration allowed continuous ash evacuation during operation, preserving production schedules during critical dyeing cycles. Second, the reciprocating grate’s ability to process high-ash cotton stalks—abundant in Pakistan’s agricultural landscape—eliminated fuel preprocessing costs while ensuring stable combustion. Third, the segmented windbox system maintained precise steam parameters essential for color consistency across large fabric batches.

Implementation underscored ZOZEN’s partnership ethos. Recognizing Soorty’s transition from coal to biomass, ZOZEN’s technical team conducted on-site commissioning with a focus on operator training tailored to textile-specific scenarios. When seasonal variations in cotton stalk moisture affected initial combustion stability, engineers refined air distribution profiles within 48 hours via remote diagnostics—avoiding weeks of manual adjustments that would have disrupted production. A dedicated project manager facilitated weekly coordination between Pakistani technicians and ZOZEN’s engineering hub, ensuring seamless integration with Soorty’s existing steam network.

Why Textile Boiler Selection Defines Sustainable Competitiveness

For textile manufacturers navigating energy transition, the textile boiler represents far more than thermal equipment—it is a strategic enabler of both environmental compliance and product quality. Its steam consistency directly impacts fabric quality; stable temperature and pressure prevent dye migration and texture variations that cause costly rejections in premium markets. Crucially, the maintenance architecture minimizes production interruptions, where even four hours of downtime can disrupt entire dyeing schedules for high-value orders.

ZOZEN’s service philosophy ensures these advantages endure throughout the equipment lifecycle. Regional technical hubs in key textile manufacturing zones provide rapid-response support, while cloud-based monitoring platforms detect combustion anomalies before they affect steam quality. For international clients, ZOZEN pre-validates documentation against local regulatory frameworks—from Pakistan’s NEQs to EU’s Ecolabel requirements—eliminating certification delays.

For mills seeking to future-proof their thermal infrastructure, the textile boiler decision transcends technical selection—it embodies a commitment to sustainable excellence. ZOZEN’s proven track record across global textile hubs demonstrates that true innovation lies not in isolated components, but in holistic solutions engineered where it matters most: within the dynamic reality of fabric production. When your reputation depends on every thread’s perfection, choose a textile boiler partner who understands that steam quality is woven into product quality.

Leave a Reply