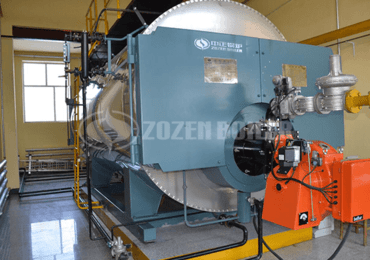

WNS Series Fire Tube Structure Steam Boiler

Product thermal capacity: 1 – 20 t/h

Working pressure: 0.7-2 MPa

Available fuel: Natural gas, coke oven gas, biogas, diesel, heavy oil, light oil, crude oil, etc.

Available industries: Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc.

WNS Series Fire Tube Structure Steam Boiler Introduction

The WNS series fire tube structure steam boiler adopts the classic three-pass fire tube design, where the fuel is fully combusted in the furnace, and the heat is transferred to the boiler water through high-efficiency heat exchange tubes, maximizing thermal efficiency with an overall efficiency of up to 98%. In addition, the WNS series boiler is equipped with advanced condenser technology to effectively recover waste heat from high-temperature flue gas, further lowering flue gas temperature and significantly reducing energy loss. Known for its stable operation and user-friendly controls, the WNS series is widely used in industries such as food processing, chemicals, and textiles. Its intelligent control system enables fully automatic operation, allowing users to monitor and adjust the boiler status in real-time via a touchscreen, ensuring safe and efficient operation. In terms of environmental performance, the WNS series boiler supports various fuel options, including natural gas and light diesel, and, when equipped with a low-nitrogen burner, can effectively control NOx emissions, meeting international environmental standards. As a technologically advanced fire tube structure steam boiler, ZOZEN’s WNS series boilers not only offer excellent performance but also reliable service, providing customers with comprehensive technical support and maintenance services, making it the ideal choice for industrial steam supply.

WNS Series Fire Tube Structure Steam Boiler Advantages

High thermal efficiency: The WNS series boiler adopts the three-pass fire tube structure, with thermal efficiency up to 98%, significantly improving energy utilization.

Energy-saving and environmentally friendly: Equipped with condenser technology, it recycles waste heat from flue gas, reducing flue gas temperature and minimizing energy waste and pollution emissions.

Intelligent control: Features a fully automatic operating system, allowing users to monitor and adjust boiler status in real-time, ensuring efficient and safe operation.

Multi-fuel compatibility: Supports multiple fuel options such as natural gas and light diesel, and can be equipped with low-nitrogen burners to meet environmental standards.

WWNS Series Fire Tube Structure Steam Boiler Specification

| Model | Rated steam capacity (t/h) | Rated working pressure (MPa) | Rated steam temperature (℃) | Maximum transport weight (t) | Maximum transport dimension (m) |

| WNS1-0.7-Q(Y) | 1 | 0.7 | 170 | 4.5 | 3.25×1.80×2.00 |

| WNS1-1.0-Q(Y) | 1 | 1 | 184 | 4.5 | 3.25×1.80×2.00 |

| WNS1.5-1.0-Q(Y) | 1.5 | 1 | 184 | 7 | 3.65×2.05×2.45 |

| WNS1.5-1.25-Q(Y) | 1.5 | 1.25 | 194 | 7 | 3.65×2.05×2.45 |

| WNS2-1.0-Q(Y) | 2 | 1 | 184 | 9 | 4.60×2.20×2.60 |

| WNS2-1.25-Q(Y) | 2 | 1.25 | 194 | 9 | 4.60×2.20×2.60 |

| WNS3-1.0-Q(Y) | 3 | 1 | 184 | 11.5 | 5.35×2.40×2.80 |

| WNS3-1.25-Q(Y) | 3 | 1.25 | 194 | 11.5 | 5.35×2.40×2.80 |

| WNS4-1.25-Q(Y) | 4 | 1.25 | 194 | 15 | 5.00×2.60×2.95 |

| WNS4-1.6-Q(Y) | 4 | 1.6 | 204 | 15 | 5.00×2.60×2.95 |

| WNS5-1.25-Q(Y) | 5 | 1.25 | 194 | 18 | 5.55×2.658×3.20 |

| WNS5-1.6-Q(Y) | 5 | 1.6 | 204 | 18 | 5.55×2.658×3.20 |

| WNS6-1.25-Q(Y) | 6 | 1.25 | 194 | 19.5 | 5.93×2.80×3.20 |

| WNS6-1.6-Q(Y) | 6 | 1.6 | 204 | 19.5 | 5.93×2.80×3.20 |

| WNS8-1.25-Q(Y) | 8 | 1.25 | 194 | 25 | 7.00×2.80×3.25 |

| WNS8-1.6-Q(Y) | 8 | 1.6 | 204 | 25 | 7.00×2.80×3.25 |

| WNS10-1.25-Q(Y) | 10 | 1.25 | 194 | 27.5 | 7.65×2.80×3.25 |

| WNS10-1.6-Q(Y) | 10 | 1.6 | 204 | 27.5 | 7.65×2.80×3.25 |

| WNS15-1.25-Q(Y) | 15 | 1.25 | 194 | 40 | 7.95×3.50×3.75 |

| WNS15-1.6-Q(Y) | 15 | 1.6 | 204 | 40 | 7.95×3.50×3.75 |

| WNS20-1.25-Q(Y) | 20 | 1.25 | 194 | 52 | 8.55×3.90×4.15 |

| WNS20-1.6-Q(Y) | 20 | 1.6 | 204 | 52 | 8.55×3.90×4.15 |

Leave a Reply