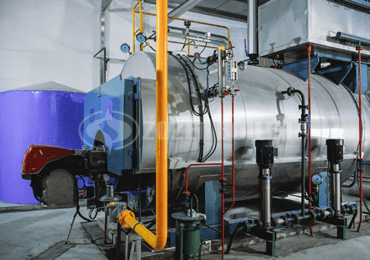

WNS Series Gas/Oil Fired Skid-mounted Steam Boiler

Product thermal capacity: 1-4 t/h

Working pressure: 1.0-1.6 MPa

Available fuel: Natural gas, biogas, coal gas, diesel oil, heavy oil, light oil, flue gases of petrochemical plants and industrial waste gas, etc.

Available industries: Chemical, food, cigarettes and tobacco, textile, building materials, hospital, heating etc.

WNS Series Gas/Oil Fired Skid-mounted Steam Boiler Introduction

- ZOZEN Boiler’s skid mounted boiler adopts an integrated design, with all auxiliary machines and accessories integrated on a single skid frame, resulting in a compact structure, rational layout, and effectively reduced footprint.

- No installation required, users only need to connect water, electricity, and gas, and it can be completed within one day, allowing for rapid deployment.

- The unique design ensures that the entire set of equipment has good mobility and flexibility.

- Customized professional burners merge the boiler control system with the burner control system, effectively enhancing the automation level of the boiler and further improving its energy-saving, environmental, and safety performance.

WNS Series Gas/Oil Fired Skid-mounted Steam Boiler Advantage

Installation free: Integrated design for quick on-site setup.

Rapid connection: Connect water, electricity, and gas for use within 1 day normally.

Compact design: Space-efficient with minimal footprint.

Flexible relocation: Easy to dismantle and reposition.

WNS Series Gas/Oil Fired Skid-mounted Steam Boiler Specification

| Model | Rated steam capacity (t/h) | Rated working pressure (MPa) | Rated steam temperature (℃) | Maximum transport dimension (m)(L×W×H) |

| WNS1-1.0-Q(Y) | 1.0 | 1.0 | 184 | 5.00×2.25×2.50 |

| WNS1-1.25-Q(Y) | 1.0 | 1.25 | 194 | 5.00×2.25×2.50 |

| WNS1.5-1.0-Q(Y) | 1.5 | 1.0 | 184 | 4.50×2.25×2.50 |

| WNS1.5-1.25-Q(Y) | 1.5 | 1.25 | 194 | 4.50×2.25×2.50 |

| WNS2-1.0-Q(Y) | 2.0 | 1.0 | 184 | 7.50×2.25×2.50 |

| WNS2-1.25-Q(Y) | 2.0 | 1.25 | 194 | 7.50×2.25×2.50 |

| WNS3-1.0-Q(Y) | 3.0 | 1.0 | 184 | 8.50×2.25×2.50 |

| WNS3-1.25-Q(Y) | 3.0 | 1.25 | 194 | 8.50×2.25×2.50 |

| WNS4-1.25-Q(Y) | 4.0 | 1.25 | 194 | 10.50×2.25×2.50 |

| WNS4-1.6-Q(Y) | 4.0 | 1.6 | 204 | 10.50×2.25×2.50 |

Leave a Reply