3 Ton Boiler: Reliable Steam Solutions from ZOZEN Boiler

In modern industrial production, the 3 ton boiler has become one of the most widely used types of medium-capacity steam equipment. It plays a crucial role in sectors such as chemical processing, food and beverage manufacturing, textiles, paper production, and pharmaceuticals. The 3 ton boiler provides sufficient steam for heating, sterilization, drying, or material transformation, all while maintaining steady operation and high energy utilization. With the increasing emphasis on environmental sustainability and cost efficiency, industrial enterprises now pay closer attention to boilers that combine energy-saving performance, safe operation, and compliance with emission standards. Among the many global boiler manufacturers, ZOZEN Boiler stands out with its advanced technology and customized steam solutions.

ZOZEN Boiler has been deeply engaged in the thermal energy field for over three decades, focusing on designing and manufacturing efficient industrial boilers for diverse industries. Its 3 ton boiler range, is widely recognized for excellent reliability, efficiency, and long service life. Both models are tailored to meet various fuel types, operating conditions, and environmental requirements, making them highly adaptable to the specific demands of modern production lines.

WNS Series Gas/Oil-Fired Steam Boiler

The WNS series is a horizontal, internal combustion, three-pass, wet back boiler, designed for clean fuel applications such as natural gas, diesel, and light oil. It features a corrugated furnace that improves heat transfer efficiency and enhances thermal expansion flexibility, ensuring stable and safe operation under high-temperature conditions.

ZOZEN 3 ton WNS gas/oil-fired boiler

The boiler’s working process is meticulously engineered for maximum thermal performance. The fuel is atomized by the burner and burned in the fully corrugated furnace, forming a high-temperature flame that transfers radiant heat through the furnace wall — this constitutes the first pass. The flue gas then flows through the reversing chamber and enters the second pass, consisting of threaded smoke tubes, where convective heat transfer takes place. Afterward, the gas passes through the third pass — smooth smoke tubes — before exiting through the rear smoke chamber and economizer, where waste heat recovery occurs to further improve efficiency.

This series of 3 ton boilers achieves a thermal efficiency of up to 98% with the addition of a condenser and economizer. Its full automatic intelligent control system allows for unattended operation, with real-time monitoring of temperature, pressure, and combustion parameters. The wet back design minimizes heat loss, while the advanced low-NOx burner ensures environmentally friendly operation. Compact structure, quiet operation, and ease of maintenance make it suitable for industries where both performance and reliability are critical.

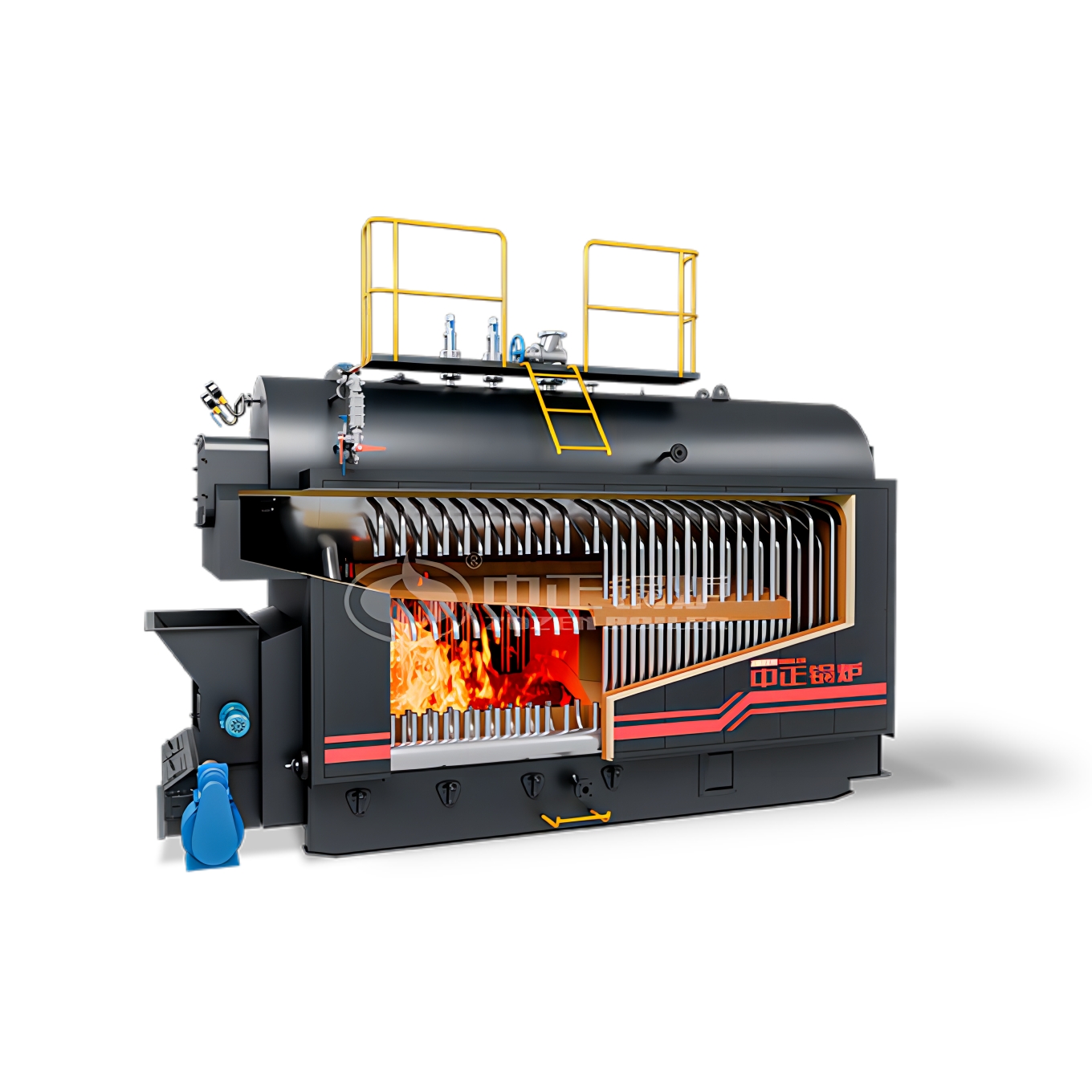

DZL Series Biomass-Fired Steam Boiler

For customers seeking renewable energy solutions, ZOZEN offers the DZL series biomass-fired 3 ton boiler, which provides a balance between energy savings and sustainability. This type of boiler uses a chain-grate stoker, allowing flexible fuel combinations such as wood chips, rice husk, palm shells, and biomass pellets. It features a tri-drum structure with a fully sealed membrane wall furnace, effectively preventing heat loss and ensuring efficient combustion.

The DZL biomass boiler adopts an independent air chamber and adjustable secondary air design, which optimize air distribution according to the combustion characteristics of the fuel. This not only improves the fuel burnout rate but also reduces unburned carbon content in the ash. The boiler’s steam-water separation system ensures excellent steam quality, suitable for industries that require stable and clean heat sources.

In terms of durability and maintenance, ZOZEN’s biomass boiler uses high-grade steel for pressure components and high-temperature zones, ensuring structural stability during long-term operation. Its intelligent control interface allows operators to easily manage feed rate, air flow, and load adjustments, achieving both energy efficiency and consistent output.

Case Study: 3 Ton WNS Boiler in Botswana

In Botswana, a well-known fragrance manufacturing company was facing challenges with its heating system. The production of essential oils and fragrances requires precise temperature control during extraction and distillation, processes that depend heavily on stable steam supply. After evaluating several suppliers, the company selected ZOZEN’s WNS3-1.25-Y 3 ton oil-fired steam boiler for its new facility.

This 3 ton boiler provided the ideal balance of efficiency, stability, and environmental compliance. Using high-quality burners and advanced control systems, the boiler maintained steady steam output throughout the production cycle, ensuring product consistency and purity. Compared to the company’s previous equipment, the WNS series offered higher fuel utilization, significantly lower emissions, and improved operating convenience.

Additionally, the adoption of this energy-efficient boiler aligned perfectly with the company’s sustainability goals. The reduction in fuel consumption and lower carbon emissions not only helped cut operating costs but also demonstrated the company’s commitment to green manufacturing. Throughout installation and commissioning, ZOZEN’s professional technical team provided on-site support and training, ensuring smooth and reliable operation from day one.

ZOZEN Boiler’s Global Strength and Service

As an international boiler manufacturer, ZOZEN Boiler has established a solid reputation in over 100 countries and regions. Its 3 ton boiler range has been widely adopted across Asia, Africa, South America, and Eastern Europe. The company’s success lies in its strong research and development capabilities, advanced production equipment, and a strict quality control system certified under ISO and CE standards.

ZOZEN’s commitment extends beyond boiler delivery. Each project benefits from comprehensive technical consultation, customized system design, and full-cycle service covering installation, training, and maintenance. The company also provides remote monitoring and technical support to ensure long-term stable performance. By integrating innovation with reliability, ZOZEN continues to supply energy-efficient boiler systems that contribute to sustainable industrial development worldwide.

Conclusion

The 3 ton boiler remains a critical component in many industrial sectors, offering the flexibility, efficiency, and reliability that modern production demands. With advanced technology, refined craftsmanship, and years of engineering experience, ZOZEN Boiler delivers superior steam solutions that help enterprises achieve efficient and sustainable growth.

Whether it is the high-performance WNS series gas/oil-fired steam boiler or the energy-saving DZL biomass-fired boiler, each ZOZEN product embodies the company’s dedication to quality and innovation. Coupled with its robust after-sales service, ZOZEN stands as a trusted global partner for industrial heat supply solutions. Choosing a ZOZEN 3 ton boiler means choosing stability, efficiency, and long-term operational assurance — essential values for every growing enterprise.

Leave a Reply