Coal Fired Steam Boilers in Pakistan

DZL series quick installation boiler is a horizontal three – return chain fire tube grate boiler with good fuel adaptability. Coal fired boilers in Pakistan for sale, and the boiler body is arranged in the longitudinal direction of a single boiler barrel, in which threaded firework pipes are arranged to form a convection heating surface. The radiant heating surface of the furnace is composed of the boiler barrel and the water cooling walls on both sides. The whole fast installation mode is delivered from the factory, and the electrical control can realize stepless speed regulation, limit parameter alarm and interlocking protection.

Coal fired boilers in Pakistan

In the coal-fired steam boilers have arched tube plate and threaded smoke tube are used to form the pot barrel, which can make the pot barrel change from a quasi-rigid body to a quasi-elastic body, and the smoke tube change from a two-return journey to a single-return journey, thus solving the problem of tube plate crack. The threaded smoke pipe is used to enhance the heat transfer effect and improve the thermal efficiency of the boiler. This series of coal-fired boilers have stable operation, convenient adjustment, full output, quick pressure boost, environmental protection, energy saving and high thermal efficiency.

The coal fired boilers in Pakistan have their own dusting effect in the whole manufacturing process, so that the soot emission of boilers can meet the national environmental protection regulations. This series of boilers adopt arched tube plate, two-wing flue, threaded pipe, etc., which solve the problems of boiler shell type, such as tube plate crack, lower drum bulge, water wall explosion, low thermal efficiency, insufficient output, poor coal quality and so on.

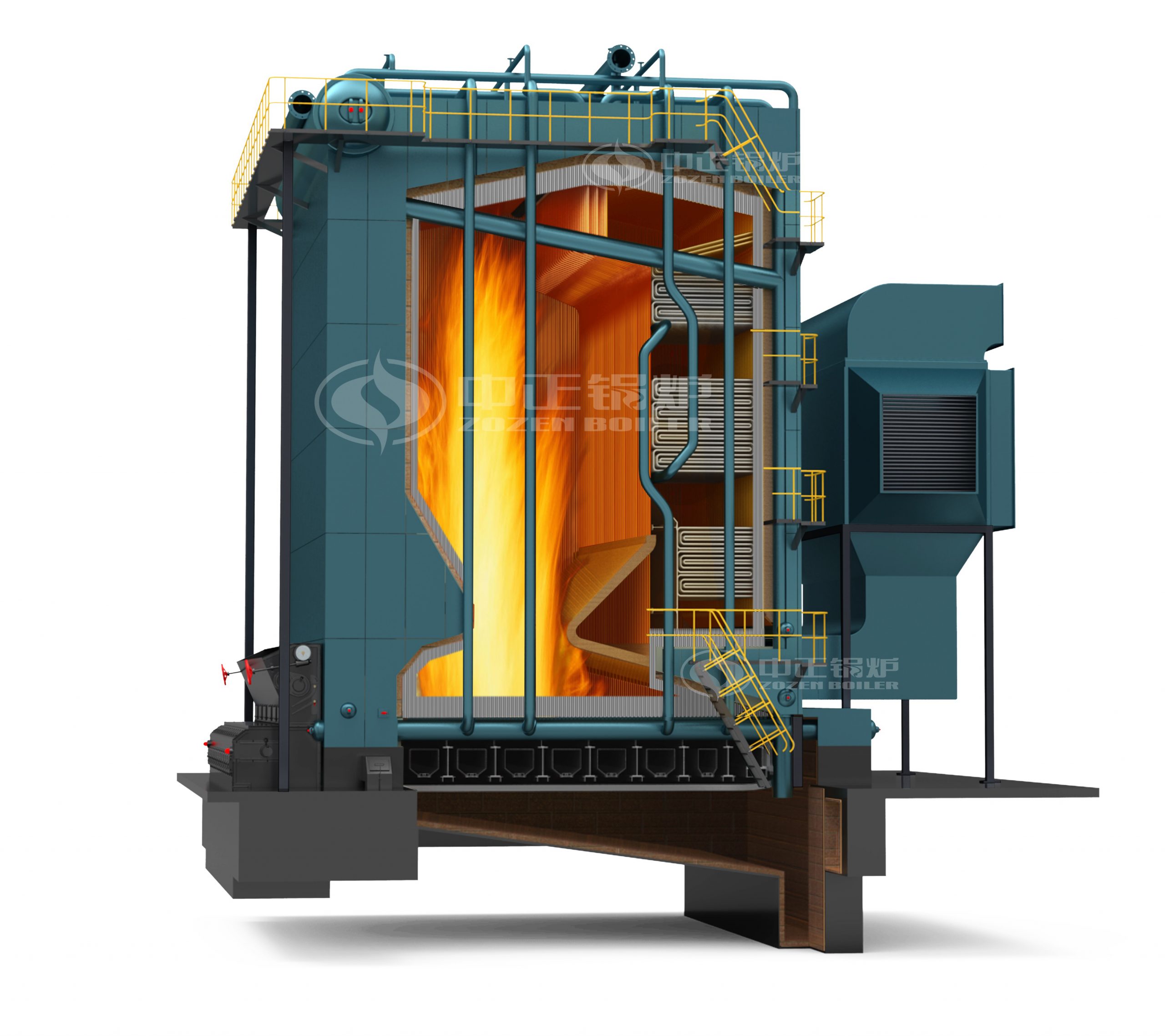

This series of industrial coal fired boilers adopt light chain grate to realize mechanical coal feeding, equipped with blower and induced draft fan for mechanical ventilation, and equipped with scraper type slag discharge machine to realize automatic slag discharge. The front and rear arches of the furnace adopt new energy saving technology. After the fuel falls on the grate from the coal sill and enters the furnace for combustion, the flame, through the refraction of the rear arch, turns upward through the burning Chambers on both sides of the body and turns to the front smoke box, and then turns back to the tube bundle in the pot by the front smoke box, enters the economizer through the rear smoke box, and then is pumped by the induced draft fan to the air through the flue to the chimney.

When the steam pressure of the boiler tube rises gradually, it is necessary to pay attention to whether there is any special sound or abnormal phenomenon in each part of the boiler. If there is any abnormal phenomenon above, it should be checked immediately. If necessary, the furnace can be shut down for inspection. After the fault is eliminated, the furnace can continue to run. During the heating of the boiler, it is necessary to monitor the outlet water temperature of the energy saving device to prevent the water in the energy saving device from vaporizing. If necessary, the valve from the energy saving device to the pot can be closed.

Industrial coal fired boilers

Coal fired boilers in Pakistan for sale mainly for chemical, food, packaging, building materials, rubber and other industrial production. Auxiliary equipment of coal-fired steam boiler includes: blower, induced draft fan, secondary fan, electric control cabinet, feed water pump, water treatment, slag eliminator, coal feeder, instrument, chimney, etc. Zozen Boilers is specialized in the coal-fired boiler manufacturers, rich technical experience, in addition to DZL series of boiler, and SZL series of coal-fired boiler, exports more than 100 countries and regions, the scene of thousands of cases, welcome to visit!

Leave a Reply