Efficient and Sustainable Biomass Boiler Plant Solutions by ZOZEN Boiler

In today’s era of sustainable industrial transformation, renewable energy technologies have become a major focus for enterprises across different sectors. Among them, the biomass boiler plant stands out as one of the most effective solutions for achieving cleaner and more efficient heat generation. By utilizing biomass fuels such as wood chips, rice husks, palm shells, and agricultural residues, biomass boiler plants help reduce carbon emissions and reliance on fossil fuels while maintaining strong thermal performance. This makes them increasingly popular in industries such as building materials, textiles, chemicals, paper manufacturing, and food processing, where stable steam supply and environmental compliance are both crucial.

A biomass boiler plant is not only a heat generation system but also an integrated energy solution designed to optimize combustion efficiency, minimize emissions, and maximize the use of renewable resources. With continuous advancements in boiler design, modern biomass boilers are now capable of achieving high thermal efficiency while maintaining consistent performance under variable load conditions. However, building an efficient and reliable biomass boiler plant requires more than just equipment — it demands engineering expertise, advanced manufacturing technology, and a comprehensive understanding of fuel characteristics.

Advanced Design and Technology of ZOZEN DZL Biomass Boiler

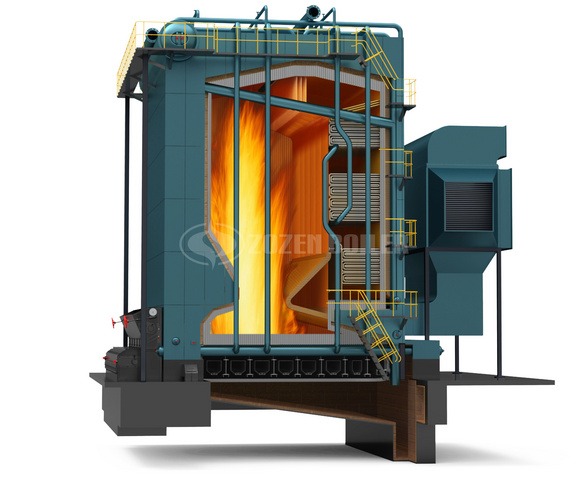

The DZL series biomass steam boiler is one of ZOZEN’s flagship products, designed and manufactured based on international advanced boiler technology and tailored to the characteristics of various biomass fuels. It adopts a three-drum, horizontal water tube configuration with a chain-grate combustion system, forming a compact, durable, and easy-to-maintain structure that provides efficient heat transfer and stable steam generation.

ZOZEN 25 ton DZL biomass-fired steam boiler

A key innovation of the DZL biomass boiler lies in its non-ash accumulation furnace design, which effectively prevents ash buildup in the furnace area, ensuring long-term steady combustion and consistent thermal performance. This design significantly reduces the maintenance frequency and operational downtime commonly associated with traditional biomass boilers.

The boiler consists of two major assemblies: the upper heating surface and the lower combustion system. The upper portion includes the steam drum, water walls, and convection heating surfaces. The water-cooled walls are arranged around the front part of the furnace, forming a complete combustion chamber that absorbs radiant heat efficiently. Behind the furnace, convection tube bundles are installed between the upper and lower drums to extract heat from the high-temperature flue gas. After transferring heat through the convective section, the flue gas is directed to the economizer and then discharged through the dust collector and chimney.

The DZL biomass boiler also features an adjustable high furnace chamber, raised by approximately one to three meters to create sufficient combustion space for unshaped biomass fuels such as wood residues and straw pellets. This enhanced furnace volume allows for more complete combustion, reducing unburned carbon content in ash and improving fuel utilization efficiency.

Another defining feature of the ZOZEN DZL series is its customizable grate system, which can be designed to suit different biomass fuels. The grate bars, air distribution, and feeding mechanism can be optimized according to the specific fuel characteristics, ensuring stable combustion and reducing slag formation. The boiler’s overall thermal efficiency exceeds 88%, reflecting ZOZEN’s dedication to energy-saving technology and performance optimization.

In terms of operational convenience, the DZL biomass boiler is equipped with a flexible soot-blowing system that allows operators to clean the heating surfaces without shutting down the unit. This not only maintains the boiler’s efficiency over time but also reduces maintenance costs and improves uptime. With its intelligent control system and robust structural design, the ZOZEN biomass boiler plant provides customers with a reliable, efficient, and environmentally friendly steam supply solution that aligns with modern industrial energy transition goals.

Case Study: ZOZEN DZL Biomass Boiler in a Green Building Materials Project

A leading new material technology company specializing in ALC (Autoclaved Lightweight Concrete) panel manufacturing was seeking an energy solution for its new production line. As a producer of prefabricated wall panels used in green construction projects, the company required a biomass boiler plant capable of delivering high-capacity and high-efficiency steam generation for continuous production.

After evaluating several solutions, the company chose ZOZEN Boiler as its energy partner. Based on the specific process requirements, ZOZEN provided a DZL series 25-ton biomass-fired steam boiler, designed to supply consistent high-temperature steam to support the curing and drying processes in ALC panel production.

The high furnace design of the DZL boiler — elevated by up to three meters — allowed it to accommodate non-molded biomass fuels, ensuring complete combustion and stable heat release. The customized chain grate system was engineered to match the client’s chosen fuel type, maximizing combustion efficiency and minimizing slag formation. This adaptability not only enhanced energy performance but also reduced the need for frequent maintenance.

Moreover, the efficient heat transfer surfaces and flexible soot-blowing system further contributed to reliable long-term operation. Operators could perform cleaning and ash removal during operation, maintaining the boiler’s efficiency without halting production. The boiler’s design efficiency of above 88% translated into substantial energy savings, helping the client achieve both environmental and economic benefits.

Why Choose ZOZEN Biomass Boiler Plant Solutions

The success of this project highlights the strength of ZOZEN Boiler’s technical design and customer-oriented approach. Each biomass boiler plant developed by ZOZEN is built upon careful consideration of the customer’s production scale, fuel source, and environmental objectives. The company’s deep understanding of biomass combustion technology enables it to design boilers that deliver both performance and sustainability.

Beyond equipment manufacturing, ZOZEN provides comprehensive support through every stage — from system design and on-site installation to operation training and maintenance. Its after-sales service network ensures rapid response and professional technical assistance, minimizing downtime and maintaining long-term reliability.

With decades of experience and a global reputation for quality, ZOZEN Boiler continues to provide energy-efficient and environmentally conscious steam systems for industries around the world. Its biomass boiler plant solutions not only meet the growing demand for renewable energy but also help customers reduce operational costs, improve productivity, and achieve their carbon reduction goals.

For companies seeking a dependable partner in their transition to cleaner industrial heating, ZOZEN’s DZL biomass boiler represents a proven, forward-looking solution — one that combines engineering excellence, adaptability, and sustainable performance.

Leave a Reply