Biomass Fuel Boiler: ZOZEN Boiler’s Efficient and Sustainable Solution for Modern Industries

In recent years, as industries across the globe pursue cleaner and more sustainable energy sources, the biomass fuel boiler has become an increasingly popular choice in sectors ranging from food processing and chemical manufacturing to agriculture and aquaculture. Biomass fuel, typically derived from agricultural and forestry residues such as wood chips, palm shells, rice husks, and sawdust, offers a renewable alternative to traditional fossil fuels. Its ability to reduce carbon emissions and operational costs makes it a valuable component of the global energy transition.

The biomass fuel boiler is distinguished by its adaptability and cost-effectiveness. It converts biomass energy into thermal energy through efficient combustion, providing steam or heat for industrial processes. Compared with fossil fuel boilers, it significantly lowers CO₂ and SO₂ emissions while utilizing locally available waste materials. The wide fuel range and flexible combustion design make it suitable for diverse industries such as food and beverage production, feed manufacturing, pharmaceuticals, textiles, and pulp and paper processing.

However, challenges remain in maintaining stable combustion and consistent steam output due to the varied physical properties of biomass fuels. This is where manufacturers with strong R&D and design capabilities—like ZOZEN Boiler—demonstrate clear advantages. With over three decades of experience in industrial boiler manufacturing, ZOZEN Boiler has developed a series of biomass solutions that combine high efficiency, fuel flexibility, and intelligent control systems.

Advanced Engineering of the DZL Series Three-Drum Biomass Fuel Boiler

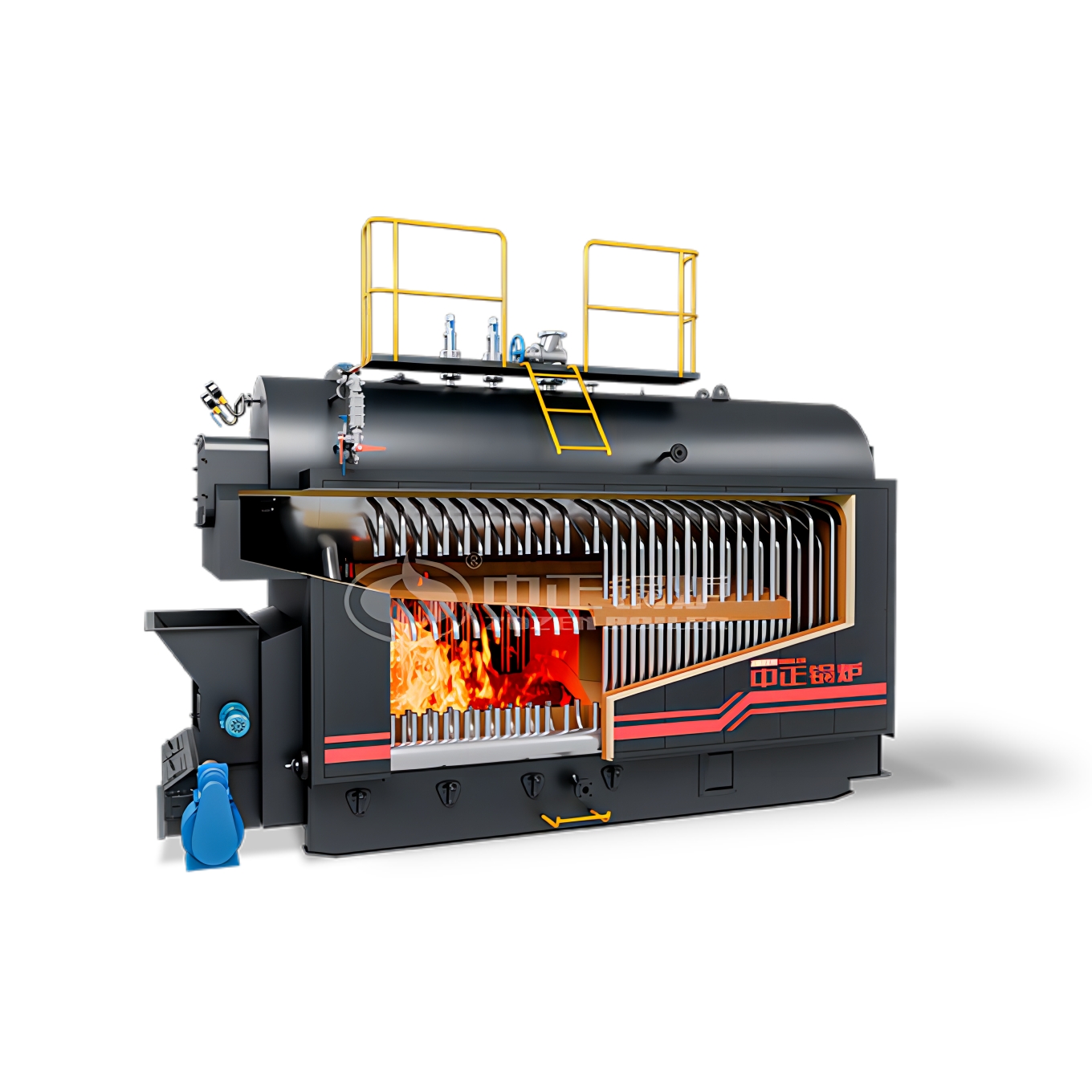

The DZL series three-drum biomass fuel boiler represents a new generation of biomass steam boilers designed by ZOZEN’s engineering team for complex fuel types and high-efficiency requirements. This model features a horizontal water-fire tube structure, equipped with a unique three-drum layout that effectively enlarges the heating surface and optimizes heat exchange. The design allows the boiler to maintain steady steam output even when the biomass fuel quality fluctuates, which is a frequent issue in industrial applications.

The furnace chamber of this biomass fuel boiler is designed with increased height—ranging from one to three meters higher than standard configurations—to accommodate non-shaped biomass fuels. This extended furnace enables complete combustion of coarse or irregular fuels like palm fiber or wood shavings, ensuring stable flame propagation and thorough heat release. Meanwhile, the threaded smoke tubes and high-efficiency convection section improve the heat transfer coefficient, helping the boiler achieve thermal efficiency of approximately 88% under stable operation.

ZOZEN 10 ton DZL biomass-fired boiler

In terms of structural configuration, the DZL series adopts a chain-grate combustion system with independent air chambers and adjustable dampers. This zoned air supply allows precise control over combustion conditions, reducing unburned carbon content and minimizing emissions. The furnace and flue gas flow are fully enclosed by membrane-type water walls, significantly lowering heat loss and enhancing mechanical strength.

A major technological advancement in ZOZEN’s biomass fuel boiler is the online automatic cleaning system. Traditional biomass boilers often suffer from ash accumulation, which can lead to reduced efficiency and unplanned downtime. The DZL three-drum design incorporates real-time cleaning without requiring shutdown, allowing continuous operation. For many users, this innovation means an additional 15 to 30 days of production capacity per year, translating directly into economic benefits.

Additionally, the boiler is integrated with ZOZEN’s intelligent control system, which supports data monitoring, combustion optimization, and fault diagnosis. Through the digital control panel, operators can easily manage combustion parameters, steam output, and safety indicators, ensuring efficient and safe performance across the entire operating cycle.

ZOZEN Biomass Fuel Boiler Empowering a Fishmeal Producer

Fishmeal production places unique demands on steam systems. Both the steaming and drying stages require high-temperature steam that is stable and responsive to load fluctuations. Inconsistent steam quality can directly affect product yield and final moisture content, while low efficiency increases operational costs. At the same time, the industry faces growing pressure to meet stricter environmental regulations and reduce energy consumption.

Recognizing these challenges, a leading fishmeal producer partnered with ZOZEN Boiler to deploy a customized 10-ton DZL series three-drum biomass fuel boiler. ZOZEN’s engineering team optimized the boiler’s combustion system and increased the furnace height by up to 3 meters to accommodate the client’s non-shaped biomass fuel mix. This customized furnace configuration ensures thorough combustion, even when the fuel varies in density and moisture content.

The boiler system also incorporates an online ash removal mechanism, allowing uninterrupted operation and eliminating the frequent cleaning shutdowns common in conventional biomass boilers. This innovation alone enables the client to gain approximately 15 to 30 extra days of productive uptime each year. The improved combustion efficiency and optimized heat transfer design contribute to an estimated 10% increase in overall thermal efficiency, directly reducing fuel consumption per unit of steam output.

The project successfully demonstrates ZOZEN’s ability to balance steam quality, energy efficiency, and environmental compliance. Through a holistic approach—combining biomass substitution, efficient heat exchange, and intelligent automation—the client achieved stable supply of high-quality steam for continuous fishmeal processing. Moreover, the system’s low emission levels and reduced maintenance needs align perfectly with the company’s strategy for sustainable, low-carbon growth in the aquaculture sector.

Technical and Service Advantages of ZOZEN Biomass Fuel Boilers

The biomass fuel boiler from ZOZEN Boiler embodies a convergence of efficiency, adaptability, and reliability. From furnace design and fuel flexibility to automatic control and emission management, every detail reflects the company’s commitment to engineering excellence and long-term performance.

ZOZEN’s design philosophy centers on creating systems that adapt to real-world production conditions rather than relying solely on theoretical efficiency values. For biomass applications, this means designing furnaces that can handle fluctuating fuel quality, moisture levels, and particle sizes without compromising steam stability. The integration of threaded flue tubes, independent air chambers, and large-capacity steam spaces ensures smooth operation even under varying loads.

Another distinguishing advantage lies in the company’s biomass fuel boiler manufacturing process. All pressure-bearing components are produced under strict quality management systems certified by international standards such as ISO and ASME. ZOZEN also maintains a comprehensive service network that includes project design consultation, on-site installation supervision, and operator training. After commissioning, users benefit from continuous technical support and online monitoring services that provide real-time operational insights.

The combination of solid engineering and robust service ensures that each biomass fuel boiler delivers consistent performance throughout its lifespan. Whether for agricultural processing, paper production, or aquaculture, ZOZEN’s boilers help enterprises lower fuel costs, improve efficiency, and achieve compliance with tightening emission standards.

Leave a Reply