Understanding Coal Fired Boiler Price and Choosing a Reliable Industrial Solution

The coal fired boiler price has become a major point of consideration for manufacturers in sectors that rely on large and stable heat output. Coal-fired boilers remain an important thermal equipment option for industries such as building materials, chemical processing, textile finishing, paper production, metal processing, wood-based panels, and flooring manufacturing. These industries require steady steam supply to support processes including heating, drying, forming, pressing, conditioning and various stages of high-temperature treatment. As industrial production grows more automated and continuous, companies must choose boilers that balance capacity, operational stability, fuel adaptability and lifetime cost.

With market expectations shifting toward energy efficiency and stable performance, companies increasingly turn to established boiler manufacturers that provide reliable designs and proven engineering. ZOZEN Boiler has become one such trusted supplier, offering a range of coal-fired boilers built with refined furnace geometry, optimized combustion and an emphasis on durability. For organizations that depend on uninterrupted steam supply, the coal fired boiler price offered by ZOZEN is evaluated alongside the company’s ability to deliver consistent heat, professional installation support and long-term service assurance.

Technical Characteristics and Advantages of the ZOZEN SZL Coal-Fired Steam Boiler

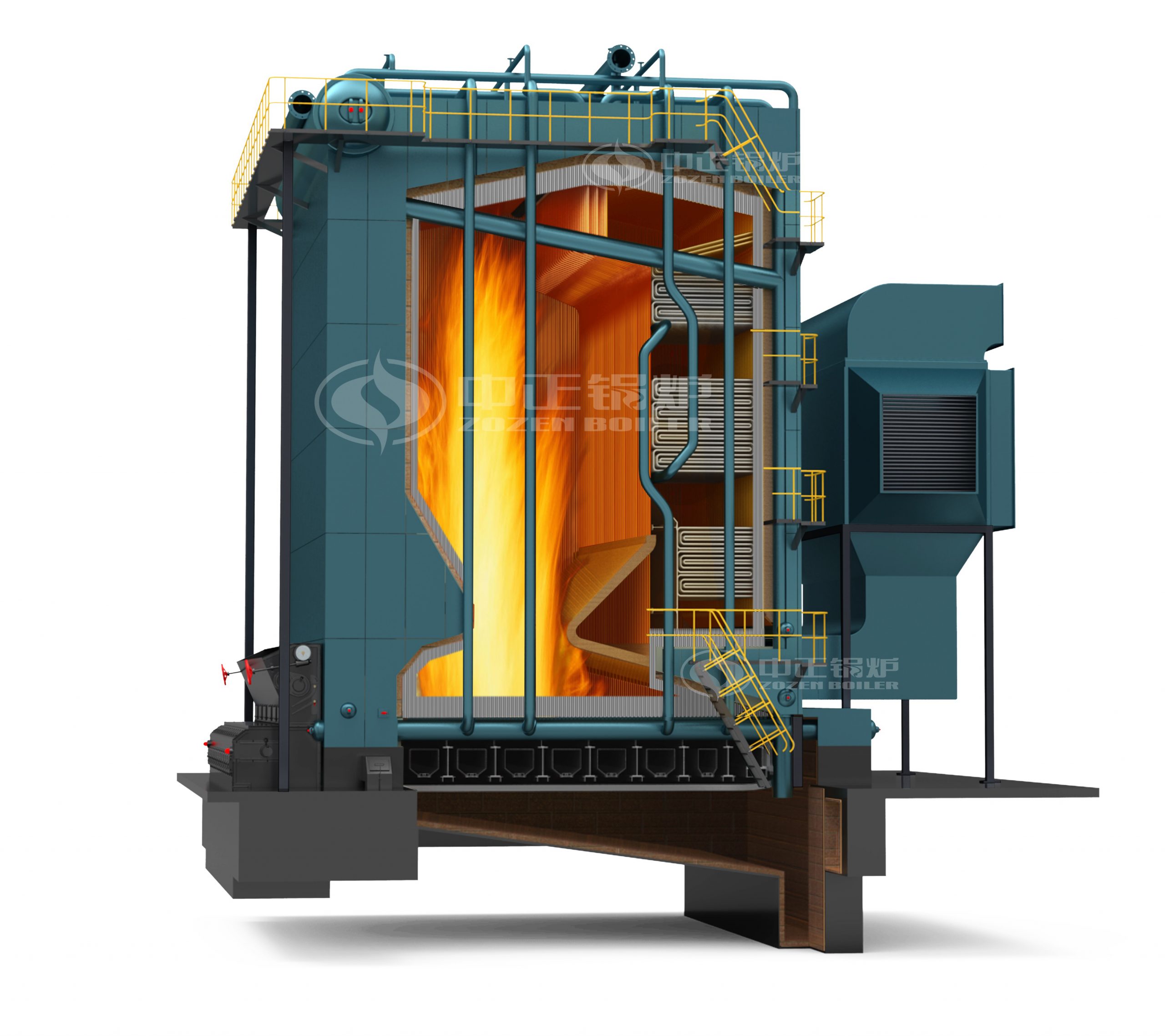

ZOZEN’s SZL series coal-fired steam boiler is widely used across industrial applications where a stable, efficient and durable steam source is essential. Although many users first compare different suppliers based on the coal fired boiler price, deeper technical evaluation often highlights the long-term benefits of the SZL’s structural design and combustion system. This boiler adopts a double-drum, vertically arranged water tube structure with the furnace placed in the center and convection heating surfaces arranged for optimal heat absorption. The structure supports efficient water circulation, balanced heat distribution and strong steam output.

ZOZEN 10 ton SZL series coal fired boiler price

A key feature of the SZL series is its layer-burning combustion method. The design integrates a scientifically shaped furnace arch that helps stabilize combustion, improve ignition conditions and enhance the burning intensity of coal. This contributes to higher heat utilization and more consistent temperature distribution throughout the furnace. By optimizing the fuel-burning environment, the boiler supports effective thermal transfer and helps enterprises manage operational energy consumption over long production cycles. This is often an essential consideration when evaluating not just the coal fired boiler price but the expected operating cost.

The SZL series also applies an independent air chamber design. Each chamber can be adjusted individually, allowing operators to fine-tune air distribution based on coal type, combustion conditions and real-time operational needs. This independence enhances combustion uniformity and enables more complete fuel burning, which is valuable for enterprises using different grades of coal or requiring flexible load adjustment. The ability to maintain stable combustion at various loads helps reduce unnecessary fuel loss and supports compliant operation. When users assess the coal fired boiler price, this adjustability becomes a factor in understanding long-term efficiency.

In addition, the boiler includes a well-arranged convection heating surface and economizer section, supporting improved heat absorption and stable steam generation. The water tube structure provides a high level of operational safety thanks to its efficient water circulation and ability to withstand long-term thermal stress. Automation components are integrated into the system to monitor pressure, water level, combustion condition and draft balance. This contributes to consistent performance and helps enterprises maintain reliable steam output with reduced manual intervention.

With the SZL series, the coal fired boiler price reflects not only the manufacturing cost but also the long-term stability of combustion, durability of heating surfaces, adaptability to production requirements and the comprehensive support offered by ZOZEN throughout installation and operation.

SZL Series Boilers Supporting Efficient Flooring Production in Vietnam

Vietnam RuiSheng New Materials Co., Ltd. is a flooring manufacturer invested by the Kenda Group. The company operates a large production facility dedicated to manufacturing new-generation flooring products, including high-density fiberboard, engineered wood flooring and other specialty materials. With a total investment of 125 million USD, the plant requires steady, high-quality steam to support various critical production stages. In flooring production lines, steam is used extensively for heating, plasticizing, pressing and temperature-controlled cooling. These processes determine the dimensional stability, texture and final quality of flooring products.

To support its full production line, the enterprise selected two 10-ton SZL series coal-fired steam boilers supplied by ZOZEN Boiler. While the coal fired boiler price was an important factor during the procurement stage, the decision was influenced more heavily by the reliability, adaptability and structural advantages of the SZL design. This series has been proven across numerous industrial applications and is well suited for production environments where stable, continuous heat is essential.

The layer-burning combustion system and specialized furnace arch help the boilers achieve stable flame formation and efficient heat transfer, helping the flooring plant maintain consistent process temperatures. The independent air chamber design enables precise control of combustion air, allowing the system to adapt to varying coal conditions and operating loads. This is especially valuable for flooring manufacturing, where process temperature must remain steady across multiple production steps.

Throughout the project, ZOZEN collaborated closely with the customer, offering support on installation, commissioning and operational adjustment. Given the significance of production continuity in flooring manufacturing, the focus was placed on ensuring that the boilers reached stable operation quickly and maintained consistent steam output. The strong performance of the SZL boilers contributed to the factory’s ability to run high-efficiency production lines and maintain the quality standards set by the Kenda Group.

Strengths of ZOZEN and Long-Term Value Beyond Coal Fired Boiler Price

As global industries continue to emphasize production stability, energy efficiency and cost management, companies increasingly evaluate the coal fired boiler price in combination with performance, durability and supplier support. A boiler must deliver consistent steam supply, reliable combustion and stable efficiency to support demanding production environments. ZOZEN Boiler meets these expectations through its SZL series coal-fired boilers, which integrate refined structural design, efficient combustion strategies and well-engineered heating surfaces.

Beyond product performance, ZOZEN provides comprehensive service including technical consultation, solution design, installation guidance, commissioning support and long-term maintenance recommendations. These services help customers protect their investment and maintain stable production without unexpected interruptions.

For enterprises evaluating coal fired boiler price while seeking dependable heat supply and professional technical support, ZOZEN Boiler offers a balanced combination of engineering strength, practical performance and reliable service—helping industries maintain stable and efficient production over the long term.

Leave a Reply