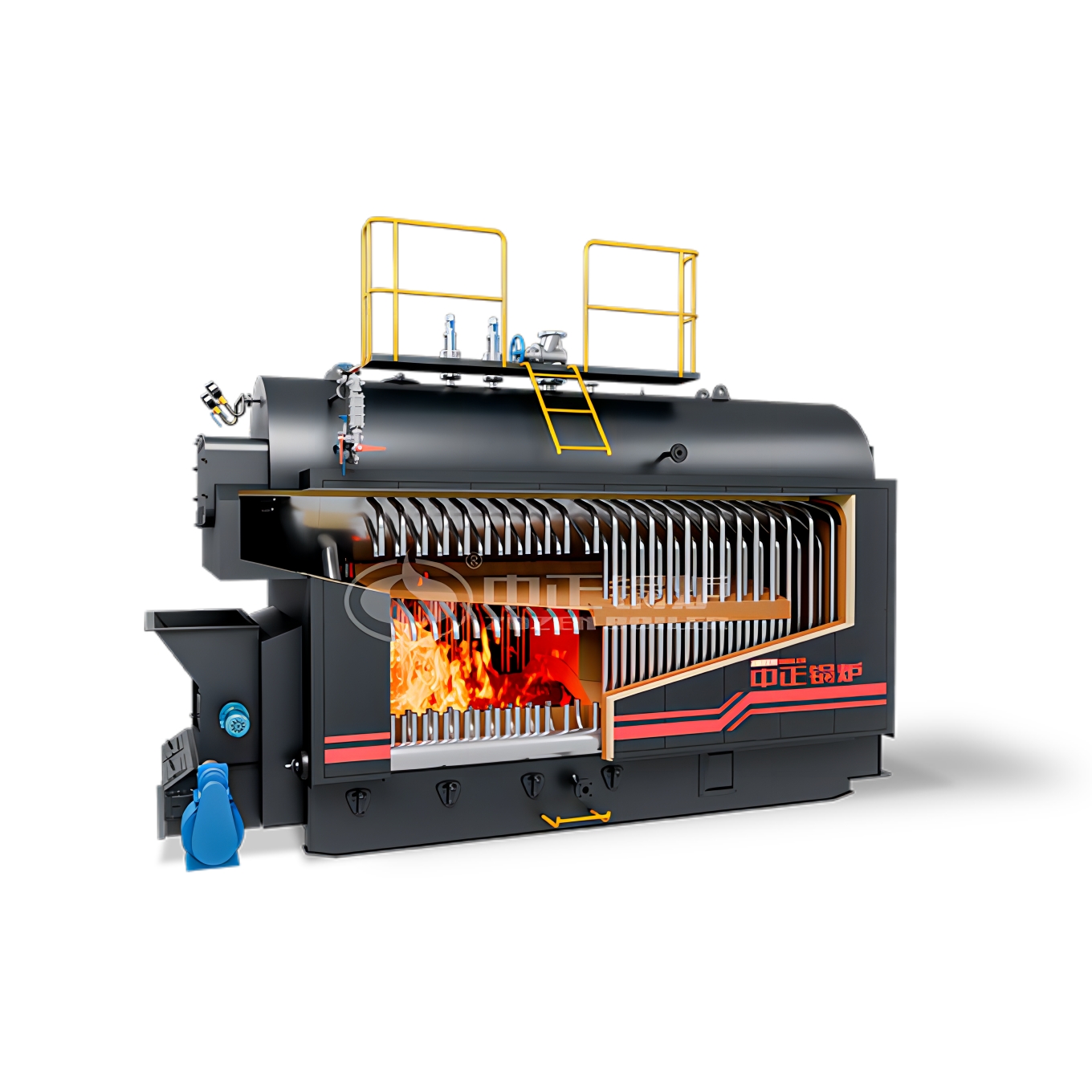

Horizontal Biomass Steam Boiler For The Pharmaceutical Industry

Biomass fired boilers used in the pharmaceutical industry are reasonably arranged for heating surfaces and combustion devices, and high-efficiency threaded smoke tubes are used. The boiler thermal efficiency is 2-5 percentage points higher than the national standard. The horizontal biomass fired boiler adopts a reasonable smoke velocity design. The heating surface of the boiler can maintain high efficiency, full load and safe operation for a long time under the condition of no dust accumulation, no wear, and no soot blowing. This type of boiler has a compact structure design and adopts quick installation or assembly to leave the factory, which is convenient for installation and shortens the installation period. The large water volume is conducive to power outage protection and has a strong ability to adapt to load changes.

Horizontal biomass fired boiler

The biomass fired boiler adopts a tall furnace, which is easy to design a reasonable furnace arch according to different fuels, improve the burning degree of the fuel and eliminate black smoke. The inertial separation of the smoke and dust at the furnace outlet of the biomass steam boiler can effectively reduce the dust concentration in the exhaust smoke and reduce the wear on the rear heating surface. The boiler adopts high-strength large grate slices or phosphorous slice grate, and the large-scale grate is equipped with a roller device to improve the safety of the grate, with less material leakage and convenient combustion adjustment.

The rear of the horizontal biomass fired boiler is equipped with a multi-tube dust collector and a bag filter. The flue gas emission is better than the prescribed standards and meets the national environmental protection requirements. This series of boiler products use high-strength large grate slices, which are suitable for the transportation and combustion of biomass boiler fuel. For large-scale grate, the roller device is installed to improve the safety of the grate and the combustion adjustment is convenient. The secondary air supply device designed by the boiler blows the flame back to prevent the flame from entering the hopper, and oxygen is supplied to promote combustion and prevent the generation of black smoke.

This series of steam boilers has a wide range of fuel applicability, and can be applied to biomass pellets, rice husks, wood chips, corn cobs, wood chips, etc. The boiler feed water adopts microcomputer control and automatic water inlet. The service life of the boiler in normal use is more than 20 years. DZL series steam boilers are easy to maintain, and require less operation and maintenance personnel, which can save you investment costs while ensuring stable operation.

The main body of the biomass fired steam boiler is a single-drum vertical arrangement, and a single-pass threaded smoke tube is arranged in the boiler. Refractory bricks do not accept high-temperature flame radiation. There are two symmetrical convection flues on both sides of the drum. In addition, the exclusive configuration is equipped with a hydroponic curved tube 750mm from the center line of the drum, which completely solves the heat stress of the drum and header. Cold shrinkage causes the disadvantages of tearing welds.

DZL series biomass boilers

The horizontal biomass fired boiler is meticulously designed by our company according to the needs of consumers and the advantages of similar products. DZL series biomass boilers are characterized by fast installation, time-saving and material-saving, compact structure and small floor space. With the advantages of high reliability, high thermal efficiency and strong overload capacity, it is the best design product of similar products.

Leave a Reply