Optimizing Biomass Boiler Efficiency: Factors and ZOZEN’s High-Quality Solutions

Biomass boilers are an environmentally friendly and sustainable alternative for generating heat and power. However, the biomass boiler efficiency can vary based on several key factors. Understanding these factors is crucial for optimizing the performance of biomass boilers and ensuring their effective operation. In this article, we will discuss the factors that influence biomass boiler efficiency and highlight the importance of selecting the right biomass boiler manufacturer.

Factors Influencing Biomass Boiler Efficiency

Fuel Quality: The quality of biomass fuel plays a significant role in determining biomass boiler efficiency. High-quality biomass with low moisture content, consistent particle size, and low impurities can enhance combustion efficiency and reduce emissions. Proper fuel storage and handling are also essential to maintain fuel quality.

Boiler Design: The design of the biomass boiler itself can impact its efficiency. Factors such as combustion chamber size, heat exchanger design, and insulation quality can affect the transfer of heat from the fuel to the working fluid. A well-designed boiler ensures optimal heat transfer and minimizes energy losses.

Combustion Control: Efficient combustion is crucial for biomass boiler performance. Accurate control of air-to-fuel ratio, proper mixing of fuel and air, and adequate residence time in the combustion chamber are essential for complete combustion and maximum heat release. Advanced combustion control systems can optimize the combustion process and improve efficiency.

Heat Recovery Systems: Biomass boilers can incorporate heat recovery systems to capture and utilize waste heat. By recovering heat from flue gases or boiler surfaces, these systems can improve overall efficiency and reduce energy wastage.

Selecting the Right Biomass Boiler Manufacturer: ZOZEN

When choosing a biomass boiler, selecting a reliable and reputable manufacturer is paramount. ZOZEN is a renowned manufacturer of biomass boilers known for their high-quality products and exceptional performance. Let’s explore some of the popular biomass boilers offered by ZOZEN:

DZL Series: The DZL series of biomass boilers offers two types. One type is the single drum water-fire tube biomass boiler, with a thermal capacity of 2-10 t/h for steam boilers and a working pressure of 1-2.5 MPa. For hot water boilers, the thermal capacity is 1.4-7 MW, with a working pressure of 1-1.6 MPa. This particular biomass boiler achieves an efficiency of over 83%. The other type is the three-drum water tube biomass boiler, with a thermal capacity of 15-40 t/h for steam boilers and a working pressure of 1.2-2.5 MPa. This biomass boiler series achieves an efficiency of at least 87.5%.

SZL Series: The SZL series biomass boilers are double drum water tube boilers. The steam boilers have a thermal capacity of 6-35 t/h, with a working pressure of 1-2.5 MPa. For hot water boilers, the thermal capacity ranges from 4.2-17.5 MW, with a working pressure of 1-1.25 MPa. These boilers boast a biomass boiler efficiency of over 86%.

DHL Series: The DHL series biomass boilers are corner tube boilers. The steam boilers have a thermal capacity of 20-75 t/h and a working pressure of 1.25-5.4 MPa. These boilers offer an impressive biomass boiler efficiency of at least 88%.

ZOZEN’s Collaboration with the Food Processing Industry

ZOZEN has recently collaborated with a prominent food processing plant involved in vegetable oil processing. The food processing industry requires a substantial amount of steam, often with strict hygiene requirements. To meet their high steam quality standards and enhance efficiency, the vegetable oil processing company decided to procure two 15-ton SZL series steam boilers from ZOZEN. With a biomass boiler efficiency exceeding 86%, these boilers enable the efficient utilization of steam for their production processes.

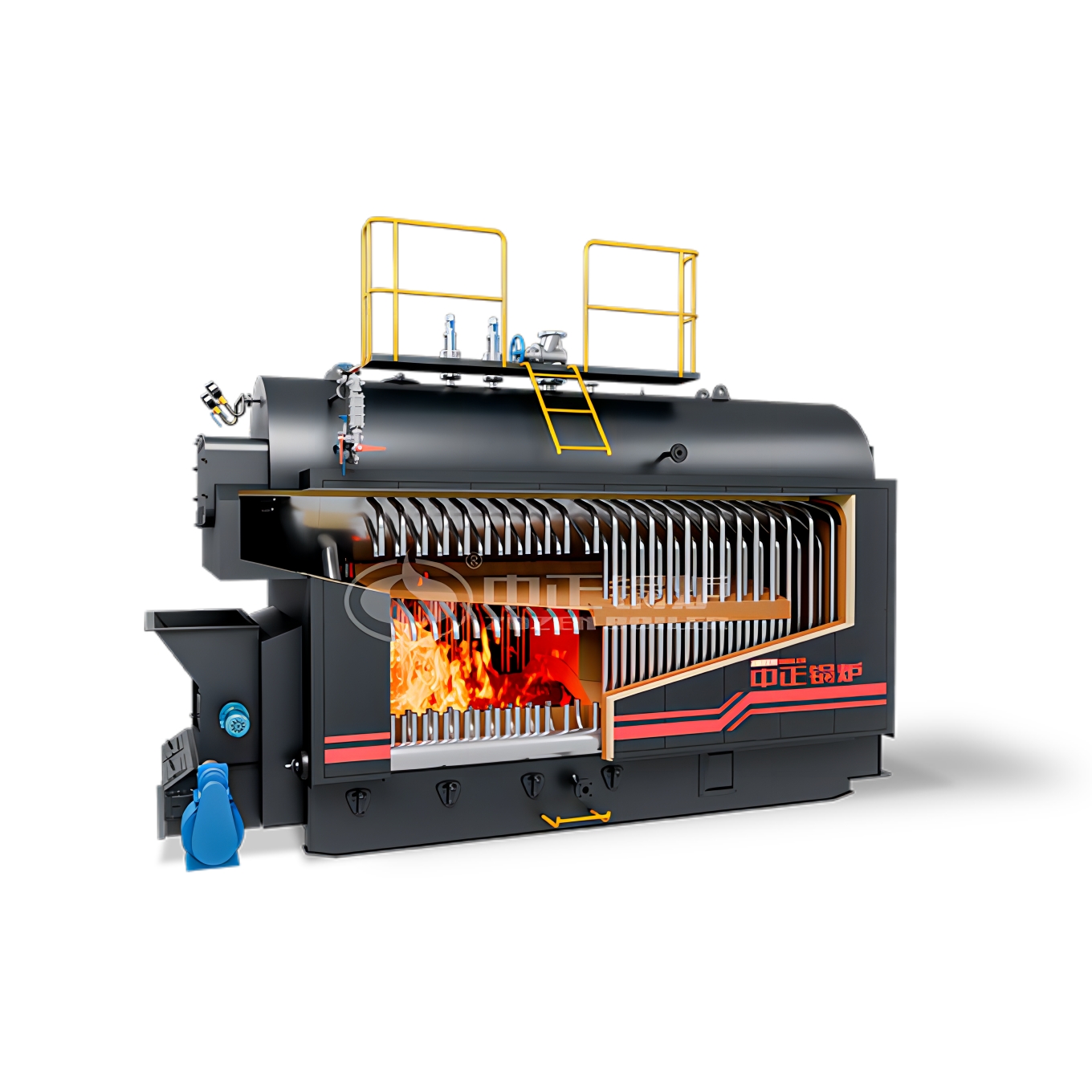

ZOZEN 15 Ton SZL Series Biomass Boiler

In conclusion, optimizing biomass boiler efficiency is crucial for sustainable and cost-effective heat and power generation. Factors such as fuel quality, boiler design, combustion control, and heat recovery systems significantly influence efficiency. Selecting a reputable manufacturer like ZOZEN ensures the availability of high-quality biomass boilers with impressive efficiency ratings. The collaboration between ZOZEN and the food processing industry exemplifies the trust and reliance placed on ZOZEN’s biomass boilers for meeting the demanding requirements of various sectors. By prioritizing efficiency and sustainability, biomass boilers contribute to a greener and more energy-efficient future.

Leave a Reply