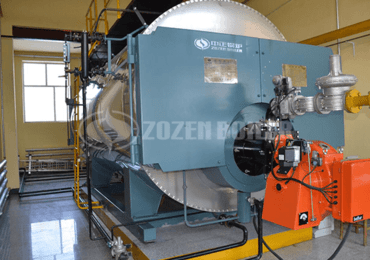

SZL Series Wood Waste Boiler

Product thermal capacity: 6-35 t/h

Working pressure: 1-2.5 MPa

Available fuel: Biomass molding granules, wood chip, corn cob, saw dust, palm shells, rice husk, etc.

Available industries: Heating, chemical, food, tobacco, textile, print and dyeing, feed, medicine, building materials, wine, hospital

SZL Series Wood Waste Boiler Introduction

The SZL series wood waste boiler is a horizontal double-drum longitudinal chain grate water tube steam boiler. Around the front end of the SZL series wood waste boiler, there are water-cooled walls arranged, connected to the upper part of the drum and to the header at the bottom, forming the combustion chamber to absorb the radiant heat of the furnace. At the rear end, dense convection tube bundles are arranged between the upper and lower drums. The high-temperature flue gas passes through the secondary return flow for cross-flow heat transfer before being led to a separately arranged economizer. Finally, it enters the dust collector and is discharged through the chimney.

SZL Series Wood Waste Boiler Technical Features

High Efficiency: The SZL series wood waste boiler adopts advanced design, achieving efficient utilization of wood waste and maximizing energy utilization efficiency.

Strong Reliability: This boiler features stable and reliable performance, meticulously designed to ensure long-term stable operation, reducing maintenance costs and failure rates.

Environmental Protection and Energy Saving: The SZL series wood waste boiler utilizes wood waste as a renewable energy source, helping to reduce greenhouse gas emissions, decrease reliance on non-renewable energy sources, aligning with the concept of environmental protection and energy conservation.

Ease of Operation: With an advanced control system, the boiler offers high automation levels for fuel supply, ash removal, and slag discharge operations, making operation and maintenance simple.

SZL Series Wood Waste Boiler Specification

| Model | Rated thermal power (t/h) | Rated working pressure (MPa) | Rated steam temperature (℃) | Maximum transport dimension (m) |

| SZL6-1.25-SCⅢ | 6 | 1.25 | 194 | 6.20×2.80×3.65 |

| 7.20×2.60×2.80 | ||||

| SZL6-1.6-SCⅢ | 6 | 1.6 | 204 | 6.20×2.80×3.65 |

| 7.20×2.60×2.80 | ||||

| SZL6-2.5-SCⅢ | 6 | 2.5 | 225 | 6.20×2.80×3.65 |

| 7.20×2.60×2.80 | ||||

| SZL8-1.25-SCⅢ | 8 | 1.25 | 194 | 7.10×3.52×3.65 |

| 7.80×3.10×2.80 | ||||

| SZL8-1.6-SCⅢ | 8 | 1.6 | 204 | 7.10×3.52×3.65 |

| 7.80×3.10×2.80 | ||||

| SZL8-2.5-SCⅢ | 8 | 2.5 | 225 | 7.10×3.52×3.65 |

| 7.80×3.10×2.80 | ||||

| SZL10-1.25-SCⅢ | 10 | 1.25 | 194 | 7.90×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL10-1.6-SCⅢ | 10 | 1.6 | 204 | 7.90×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL10-2.5-SCⅢ | 10 | 2.5 | 225 | 7.90×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL12-1.25-SCⅢ | 12 | 1.25 | 194 | 8.80×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL12-1.6-SCⅢ | 12 | 1.6 | 204 | 8.80×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL12-2.5-SCⅢ | 12 | 2.5 | 225 | 8.80×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL15-1.25-SCⅢ | 15 | 1.25 | 194 | 9.60×3.20×3.65 |

| 8.30×3.30×3.00 | ||||

| SZL15-1.6-SCⅢ | 15 | 1.6 | 204 | 9.60×3.20×3.65 |

| 8.30×3.30×3.00 | ||||

| SZL15-2.5-SCⅢ | 15 | 2.5 | 225 | 9.60×3.20×3.65 |

| 8.30×3.30×3.00 | ||||

| SZL20-1.25-SCⅢ | 20 | 1.25 | 194 | 10.65×3.28×3.60 |

| 9.30×3.81×2.80 | ||||

| SZL20-1.6-SCⅢ | 20 | 1.6 | 204 | 10.65×3.28×3.60 |

| 9.30×3.81×2.80 | ||||

| SZL20-2.5-SCⅢ | 20 | 2.5 | 225 | 10.65×3.28×3.60 |

| 9.30×3.81×2.80 | ||||

| SZL25-1.25-SCⅢ | 25 | 1.25 | 194 | 11.65×3.80×3.60 |

| 9.30×3.81×3.00 | ||||

| SZL25-1.6-SCⅢ | 25 | 1.6 | 204 | 11.65×3.80×3.60 |

| 9.30×3.81×3.00 | ||||

| SZL25-2.5-SCⅢ | 25 | 2.5 | 225 | 11.65×3.80×3.60 |

| 9.30×3.81×3.00 | ||||

| SZL30-1.25-SCⅢ | 30 | 1.25 | 194 | 10.00×3.36×3.60 |

| SZL30-1.6-SCⅢ | 30 | 1.6 | 204 | 10.00×3.36×3.60 |

| SZL30-2.5-SCⅢ | 30 | 2.5 | 225 | 10.00×3.36×3.60 |

| SZL35-1.25-SCⅢ | 35 | 1.25 | 194 | 10.00×3.65×3.85 |

| SZL35-1.6-SCⅢ | 35 | 1.6 | 204 | 10.00×3.65×3.85 |

| SZL35-2.5-SCⅢ | 35 | 2.5 | 225 | 10.00×3.65×3.85 |

Leave a Reply